- All

- Product Name

- Product Keyword

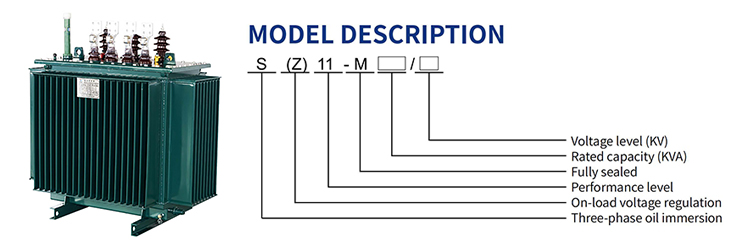

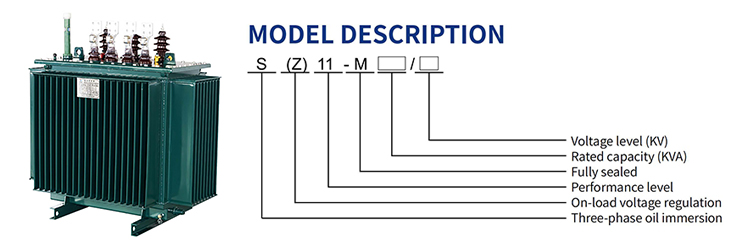

- Product Model

- Product Summary

- Product Description

- Multi Field Search

S11-M-63/6

SHENGTE

| Availability: | |

|---|---|

| Quantity: | |

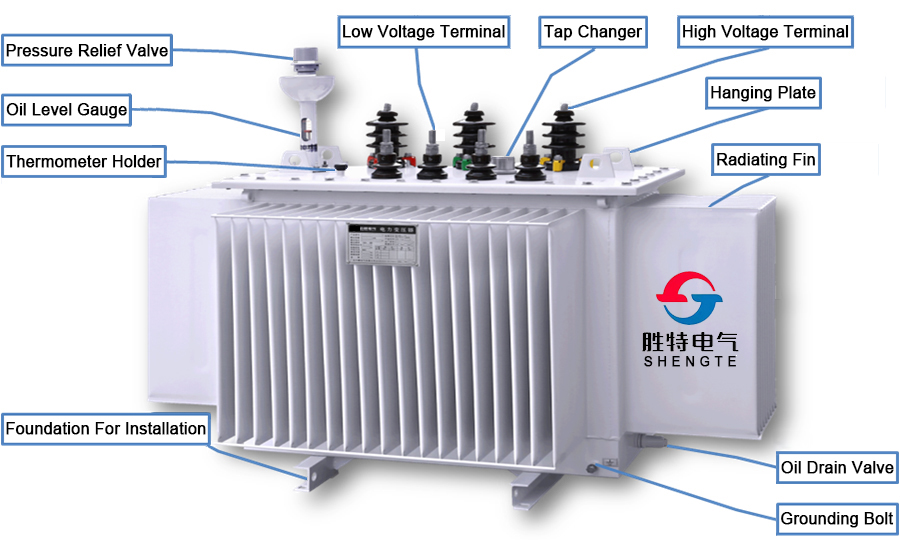

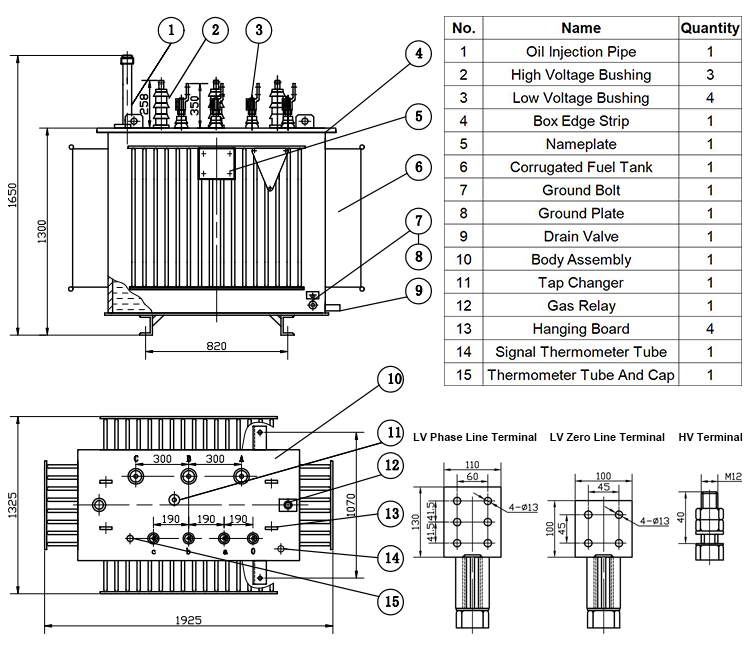

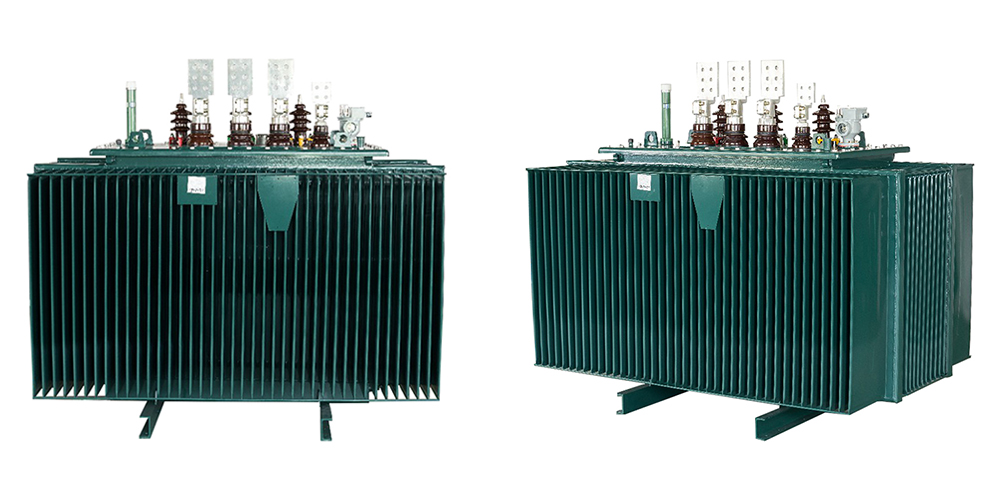

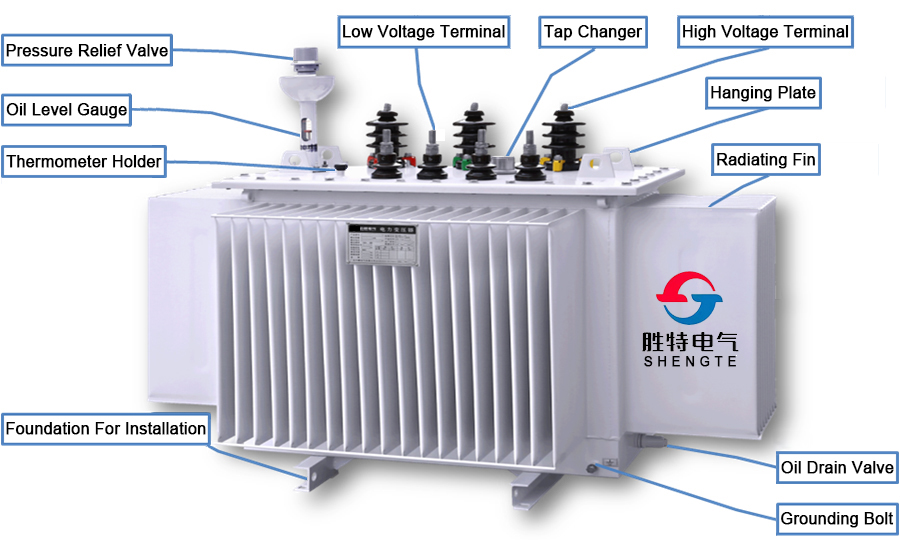

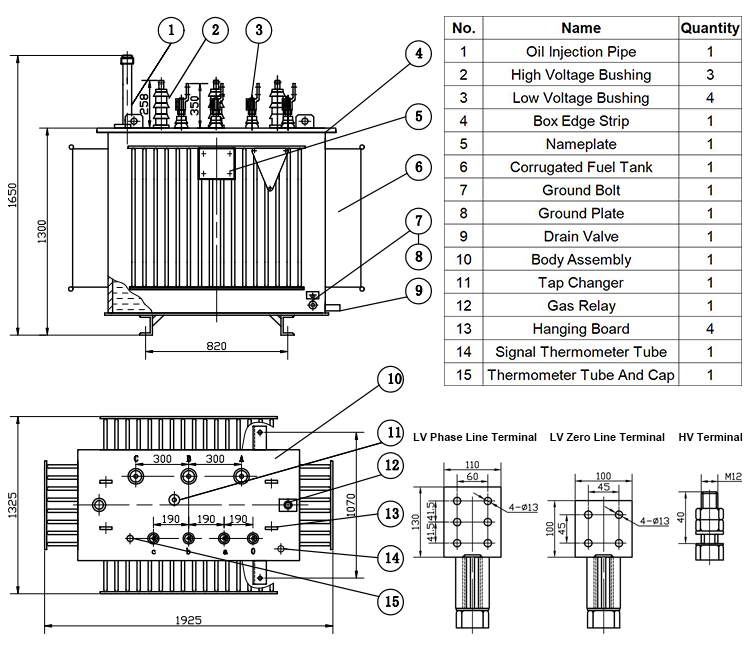

Oil immersed transformer use oil as the main insulation medium and rely on oil as the cooling medium. It adopts a sealed structure to completely isolate the transformer oil from the surrounding air, making the operation of the transformer safer, more reliable, and easier to maintain.

Features:

1. The high-voltage and low-voltage winding of oil immersed transformer generally adopt a cylindrical structure, which ensures a balanced distribution of ampere turns.

2. The coil and core are vacuum dried, and the transformer oil is filtered and injected through a vacuum process.

3. The oil tank adopts corrugated plates, which can compensate for the volume change of oil caused by temperature changes.

Our Advantages:

1. The spiral coil with longitudinal oil duct, has the performance of good heat dissipation, low magnetic leakage, high mechanical strength; And the reliable supporting structure can greatly improve the short circuit withstand ability.

2. The iron core adopts the stacked structure, it is composed of the silicon steel sheets with thickness less than 0.35mm and high magnetic conductivity, which can reduce the no-load loss and no-load current of the transformer.

3. The insulation materials have high heat resistance, which can withstand overvoltage and overcurrent during operation.

4.The transformer oil has low viscosity, good heat transfer performance and insulation performance, which can effectively protect the iron core and winding, reduce the aging of the insulation materials, and extend the service life of the transformer.

5. The corrugated oil tank is manufactured from high-quality cold-rolled steel plates on a dedicated production line, its surface is treated with deoiling, rust removal, and phosphating before being coated with a three proof (rain proof, moisture proof, and salt spray proof) paint, which can enhance operational reliability and durability, reduce the maintenance costs.

6. The sealing rings are made of the high-quality rubber materials, which can effectively slow the aging process, isolate the external air and prevent the transformer oil leakage.

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| S11-M-30 | 30 | 6 6.3 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 100 | 630/600 | 1.5 | 4 |

S11-M-50 | 50 | 130 | 910/870 | 1.3 | 4 | ||||

S11-M-63 | 63 | 150 | 1090/1040 | 1.2 | 4 | ||||

S11-M-80 | 80 | 180 | 1310/1250 | 1.2 | 4 | ||||

S11-M-100 | 100 | 200 | 1580/1500 | 1.1 | 4 | ||||

S11-M-125 | 125 | 240 | 1890/1800 | 1.1 | 4 | ||||

S11-M-160 | 160 | 280 | 2310/2200 | 1 | 4 | ||||

S11-M-200 | 200 | 340 | 2730/2600 | 1 | 4 | ||||

S11-M-250 | 250 | 400 | 3200/3050 | 0.9 | 4 | ||||

S11-M-315 | 315 | 480 | 3830/3650 | 0.9 | 4 | ||||

S11-M-400 | 400 | 570 | 4520/4300 | 0.8 | 4 | ||||

S11-M-500 | 500 | 680 | 5410/5150 | 0.8 | 4 | ||||

S11-M-630 | 630 | 810 | 6200 | 0.6 | 4.5 | ||||

S11-M-800 | 800 | 980 | 7500 | 0.6 | 4.5 | ||||

S11-M-1000 | 1000 | 1150 | 10300 | 0.6 | 4.5 | ||||

S11-M-1250 | 1250 | 1360 | 12000 | 0.5 | 4.5 | ||||

S11-M-1600 | 1600 | 1640 | 14500 | 0.5 | 4.5 | ||||

S11-M-2000 | 2000 | 1940 | 18300 | 0.4 | 5 | ||||

S11-M-2500 | 2500 | 2290 | 21200 | 0.4 | 5 | ||||

S11-M-3150 | 3150 | 2730 | 24300 | 0.4 | 5 | ||||

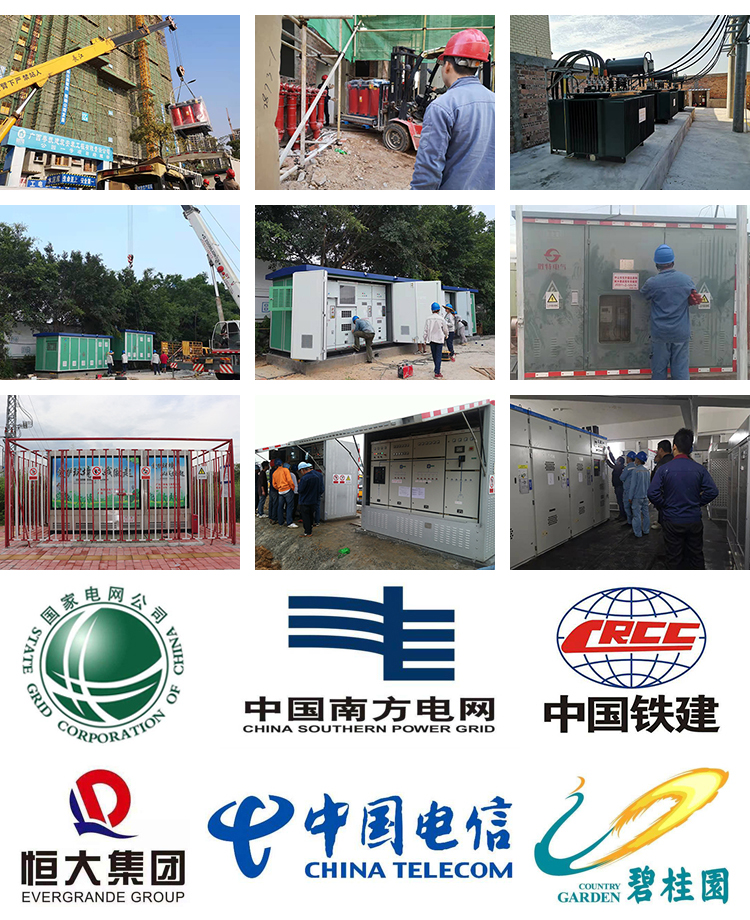

Guangdong Shengte Electric Co., Ltd. is located in Danzao Town, Nanhai District, Foshan City. It is an innovative enterprise focusing on green power distribution, energy saving and environmental protection. The power distribution products mainly include: S11 / S13 oil immersed transformer; SH15 amorphous alloy oil immersed transformer; SCB10 / SCB11 epoxy resin cast dry transformer; SGB11 open transformer; Combined (American) transformer; Pre-installed (European) substation; High and low voltage electrical equipment. It has become a qualified supplier of well-known enterprises such as China Southern Power Grid, State Grid, Evergrande Real Estate, China Railway, etc. The sales network covers most provinces and cities in the country and has been continuously expanded to overseas markets, such as Germany, Austria, Russia, etc.

Our advantages:

1. We have more than 15 years of manufacturing experience in the electric industry.

2. We have passed the ISO9001 and CE certification, the product quality accords with IEC standard.

3. Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

4. We have advanced transformer production and testing equipments, and innovative technology.

5. We have a group of professional R & D and design personnel, installation and after-sales team.

6. We can provide professional OEM & ODM service.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

Oil immersed transformer use oil as the main insulation medium and rely on oil as the cooling medium. It adopts a sealed structure to completely isolate the transformer oil from the surrounding air, making the operation of the transformer safer, more reliable, and easier to maintain.

Features:

1. The high-voltage and low-voltage winding of oil immersed transformer generally adopt a cylindrical structure, which ensures a balanced distribution of ampere turns.

2. The coil and core are vacuum dried, and the transformer oil is filtered and injected through a vacuum process.

3. The oil tank adopts corrugated plates, which can compensate for the volume change of oil caused by temperature changes.

Our Advantages:

1. The spiral coil with longitudinal oil duct, has the performance of good heat dissipation, low magnetic leakage, high mechanical strength; And the reliable supporting structure can greatly improve the short circuit withstand ability.

2. The iron core adopts the stacked structure, it is composed of the silicon steel sheets with thickness less than 0.35mm and high magnetic conductivity, which can reduce the no-load loss and no-load current of the transformer.

3. The insulation materials have high heat resistance, which can withstand overvoltage and overcurrent during operation.

4.The transformer oil has low viscosity, good heat transfer performance and insulation performance, which can effectively protect the iron core and winding, reduce the aging of the insulation materials, and extend the service life of the transformer.

5. The corrugated oil tank is manufactured from high-quality cold-rolled steel plates on a dedicated production line, its surface is treated with deoiling, rust removal, and phosphating before being coated with a three proof (rain proof, moisture proof, and salt spray proof) paint, which can enhance operational reliability and durability, reduce the maintenance costs.

6. The sealing rings are made of the high-quality rubber materials, which can effectively slow the aging process, isolate the external air and prevent the transformer oil leakage.

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| S11-M-30 | 30 | 6 6.3 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 100 | 630/600 | 1.5 | 4 |

S11-M-50 | 50 | 130 | 910/870 | 1.3 | 4 | ||||

S11-M-63 | 63 | 150 | 1090/1040 | 1.2 | 4 | ||||

S11-M-80 | 80 | 180 | 1310/1250 | 1.2 | 4 | ||||

S11-M-100 | 100 | 200 | 1580/1500 | 1.1 | 4 | ||||

S11-M-125 | 125 | 240 | 1890/1800 | 1.1 | 4 | ||||

S11-M-160 | 160 | 280 | 2310/2200 | 1 | 4 | ||||

S11-M-200 | 200 | 340 | 2730/2600 | 1 | 4 | ||||

S11-M-250 | 250 | 400 | 3200/3050 | 0.9 | 4 | ||||

S11-M-315 | 315 | 480 | 3830/3650 | 0.9 | 4 | ||||

S11-M-400 | 400 | 570 | 4520/4300 | 0.8 | 4 | ||||

S11-M-500 | 500 | 680 | 5410/5150 | 0.8 | 4 | ||||

S11-M-630 | 630 | 810 | 6200 | 0.6 | 4.5 | ||||

S11-M-800 | 800 | 980 | 7500 | 0.6 | 4.5 | ||||

S11-M-1000 | 1000 | 1150 | 10300 | 0.6 | 4.5 | ||||

S11-M-1250 | 1250 | 1360 | 12000 | 0.5 | 4.5 | ||||

S11-M-1600 | 1600 | 1640 | 14500 | 0.5 | 4.5 | ||||

S11-M-2000 | 2000 | 1940 | 18300 | 0.4 | 5 | ||||

S11-M-2500 | 2500 | 2290 | 21200 | 0.4 | 5 | ||||

S11-M-3150 | 3150 | 2730 | 24300 | 0.4 | 5 | ||||

Guangdong Shengte Electric Co., Ltd. is located in Danzao Town, Nanhai District, Foshan City. It is an innovative enterprise focusing on green power distribution, energy saving and environmental protection. The power distribution products mainly include: S11 / S13 oil immersed transformer; SH15 amorphous alloy oil immersed transformer; SCB10 / SCB11 epoxy resin cast dry transformer; SGB11 open transformer; Combined (American) transformer; Pre-installed (European) substation; High and low voltage electrical equipment. It has become a qualified supplier of well-known enterprises such as China Southern Power Grid, State Grid, Evergrande Real Estate, China Railway, etc. The sales network covers most provinces and cities in the country and has been continuously expanded to overseas markets, such as Germany, Austria, Russia, etc.

Our advantages:

1. We have more than 15 years of manufacturing experience in the electric industry.

2. We have passed the ISO9001 and CE certification, the product quality accords with IEC standard.

3. Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

4. We have advanced transformer production and testing equipments, and innovative technology.

5. We have a group of professional R & D and design personnel, installation and after-sales team.

6. We can provide professional OEM & ODM service.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.