Distribution transformer is an important part of power distribution system and plays a pivotal role. These transformers are responsible for reducing the voltage on high voltage power lines to usable levels for residential, commercial and industrial use. The makeup of a transformer is a complex system of various components that work together to ensure efficient power distribution.

The cores of distribution transformers are usually made of high-quality laminates of magnetic material that are stacked together to form a solid core. This design reduces energy loss and increases efficiency by minimizing leakage flux. The core is surrounded by primary and secondary coils which are wound around it in a specific way. The primary coil is connected to a power source, while the secondary coil is connected to a load that receives power.

The insulation of the transformer is critical to prevent the coils from touching each other, which could cause a short circuit. Insulation is also important to protect transformers from dust, dirt, moisture, and other contaminants that can damage transformer components. The insulation design can withstand high voltage and high temperature, ensuring the safe and smooth operation of the transformer.

The oil tank of a distribution transformer is another important component that helps regulate its temperature and lubricate its moving parts. The oil acts as an insulator, helping to dissipate the heat generated during transformer operation. The tank is also designed to withstand extreme pressures, ensuring efficient oil circulation within the transformer.

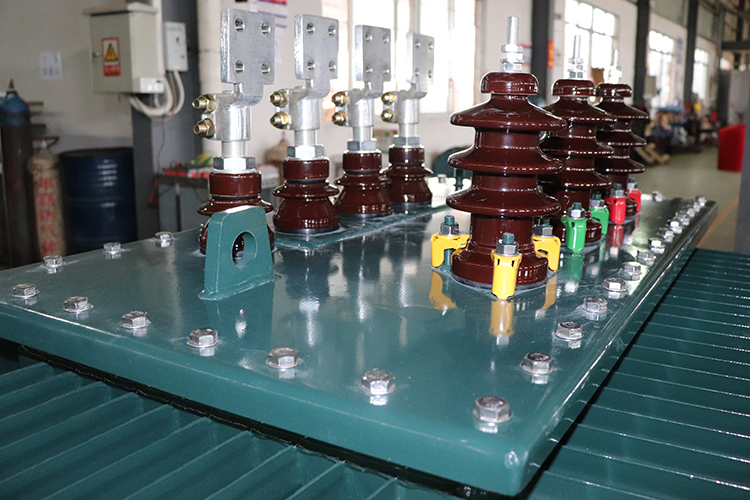

The bushings of the transformer provide the necessary insulation for the input and output power wires. The bushing is made of high-quality insulating material, which can withstand high pressure and high temperature. They are essential for transferring electrical energy from transformers to power lines while preventing energy leakage.

The cooler of the distribution transformer is another important component that helps regulate the temperature of the transformer. Coolers are critical to extending the life of transformers by preventing degradation of insulation and other components. A cooler is usually a fan or heat sink that helps dissipate the heat generated by the transformer’s operation.

To sum up, the distribution transformer is a key component in the power distribution system, and its composition is a complex system composed of various components. Iron cores, primary and secondary coils, insulators, oil filled tanks, bushings and coolers work together to ensure efficient power distribution. Understanding the makeup of a transformer is critical to ensuring its safe and smooth operation and the long life of its components.

Post time: Apr-17-2023