- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-09 Origin: Site

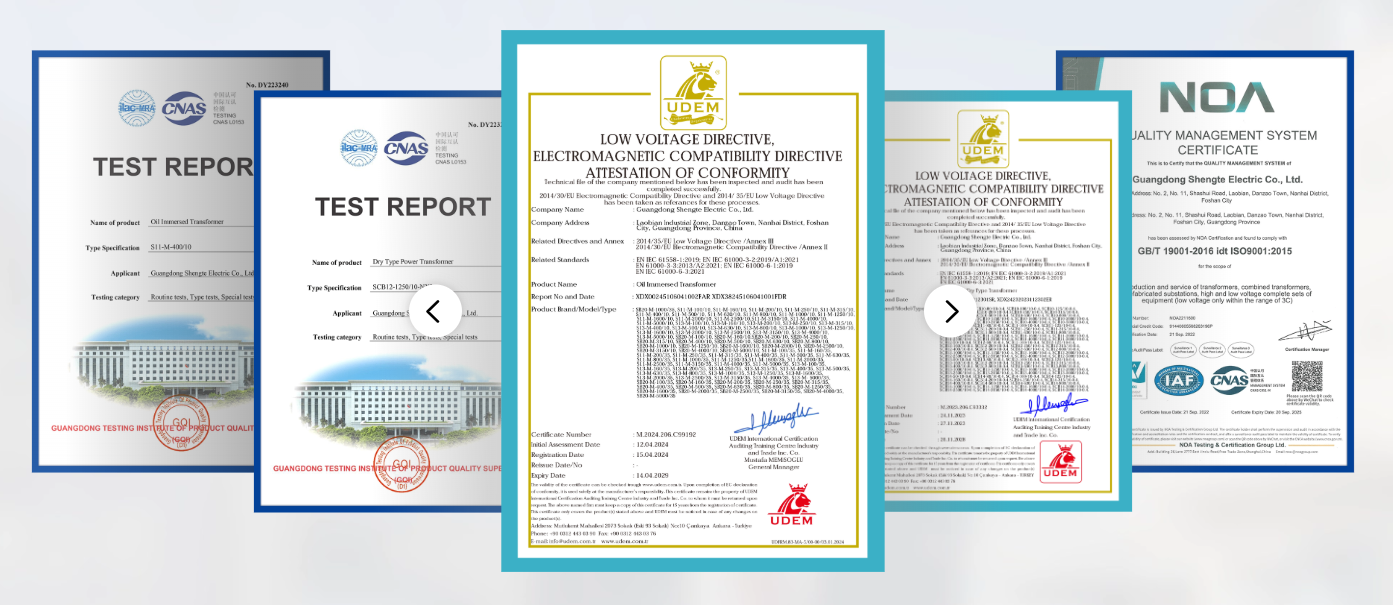

1. Certifications and Quality Assurance

2. Technical Capabilities and Product Performance

3. After-Sales Service and Technical Support

4. Supply Chain Reliability and Partnership Value

Global power grids face bigger strains than ever. Demand for electricity surges in cities and industries alike. At the same time, old infrastructure strains under the weight. Upgrades roll out worldwide to handle renewables and electric vehicles. Yet supply chains for key parts like transformers hit snags from raw material shortages to trade hurdles. In this mix, picking a solid transformer supplier turns into a core choice. It affects costs, downtime, and even grid safety. A wrong pick might mean blackouts or extra bills. But the right one keeps things running smooth.

This piece looks at why transformer suppliers matter so much now. We cover the big picture of grid shifts and chain woes. Then we break down ways to judge suppliers on quality marks, tech skills, support after the sale, and chain strength. Think of it as a guide for buyers in utilities or factories. You want partners who deliver power transformers that last. Or custom transformers fitted just right. After reading this article, you will realize the importance of choosing a trustworthy transformer equipment supplier.

Certifications act as proof of trust. They show a transformer supplier meets base rules for safety and build. Without them, risks climb—from fires to failures under load. In 2025, with tighter regs on energy gear, these marks carry extra weight. Grids push for green standards, too. So a good electrical equipment supplier holds papers that match global needs. Standards vary by region. But core ones pop up everywhere. They cover design, tests, and factory checks. A top transformer manufacturer chases these to open doors in new markets.

This base leads to inner checks. Once certs are in place, a firm's own systems keep quality steady. It's not just about passing a test. It's daily habits that build reliable power transformers or transformer substations.

Rules set the floor. Take China's GB/T 19212.5-2025. It spells out rules for power transformer builds. Focus falls on insulation and short-circuit strength. Miss it, and exports stall. Then there's IEC 60076 for dry-type transformers. It digs into efficiency and heat limits. Oil-immersed models follow similar paths under IEEE C57.12.00.

These aren’t optional. They tie to insurance and grid ties. A compact substation manufacturer without them faces fines or bans. SHENGTE holds IEC, UL, CE, and more. Its oil-immersed transformers pass these with room to spare.

Why delve into this? A single failed certification could bring a project to a halt. Imagine a hospital substation going offline, or a factory production line shutting down. Reliable certifications from transformer suppliers can mitigate these risks. They prove the equipment can withstand real-world shocks like power surges or earthquakes.

Transitioning from broad rules, firms layer on their own controls. These inner systems turn certs into everyday wins. They spot flaws early and fix them fast.

Internal setup is crucial. ISO 9001 certification leads the industry. It covers the entire process from design to shipment. SHENGTE fully implements the ISO 9001 system in its factories. They test every batch of products—including windings, cores, and tanks. Testing steps include raw material inspection, weld scanning, and load operation. For custom transformers, adjustments are made during the production process to ensure that no errors are missed. This effectively reduces the defect rate. The return rate of its cast-resin dry-type transformers is less than 0.5%.

Consistent quality means less waste and builds trust. As an electrical equipment supplier, SHENGTE provides audit reports upon request. This open attitude fosters long-term partnerships.

From these foundations, eyes turn to what the gear does. Performance metrics tell if a power transformer pulls its weight. They link straight to certs but go further into daily use.

Quality signals opportunity, but technological depth determines whether a device can thrive. In 2025, grids lean on smart links and green flows. Transformers must match. A weak one drags efficiency. Or fails in heat waves. Strong transformer manufacturers test limits. They craft pieces that fit rising needs—like handling solar spikes.

Performance boils down to numbers. But behind them sit skills in build and tweak. SHENGTE’s product series covers dry-type transformers, oil-immersed transformers, and pad-mounted ones. Each ties to the substation work. As a compact substation manufacturer, we blend these for full setups.

Numbers don’t lie. Energy loss tops the list. For power transformers, aim under 1% at full load. SHENGTE's oil-immersed models hit 0.8%. That saves kWh yearly. Temperature rise follows. Keep it below 65°C for dry-types. Exceed, and life shortens. Insulation levels guard against arcs. Class H hits 180°C. Protection ratings like IP54 block dust and sprays.

This also applies to substations. Prefabricated substations must be compact and have minimal losses. Ignoring these requirements can lead to escalating electricity costs and grid failures. Metrics set the standard. But the real gains come from continuously exceeding it. This is where R&D comes in. It develops improvements for the grid of the future.

R&D fuels the fire. SHENGTE’s center holds patents on coil winds and smart sensors. They tweak dry-type transformers for low noise—under 50dB. Oil-immersed get ester fluids for fire safety. Customized transformers are particularly outstanding. Customized services can be tailored to the specific needs of customers. As transformer manufacturers, we adapt to IEC 61850 for smart substations.

For example, ester-filled designs can reduce fire risks by 90%, amorphous iron cores have 70% lower losses than silicon steel sheets, and modular designs can speed up the installation of underground substations. These aren’t empty promises; they actually reduce operating costs.

Technology sets the stage. But gear fails without care. After-sales turns buys into bonds. It keeps transformer substations humming for years.

Sales end at delivery. But real tests start then. A power transformer might hum fine day one. So what happens in the fifth month? A voltage spike or fault might occur. Weak support means repairs are done individually, leading to skyrocketing costs. Strong transformer suppliers build teams to handle long-term operations. SHENGTE provides end-to-end support, from on-site inspections to remote scanning. Our compact substation manufacturing includes train-outs. Buyers can learn adjustment methods on-site.

Comprehensive Maintenance & Support: Yearly checks spot wear. SHENGTE sends techs for oil tests or coil scans. Tools like partial discharge gear flag issues early. Troubles? 24/7 lines link to Foshan. A dry-type transformer overheats? They guide resets. Or ship kits overnight. For transformer substations, full audits cover breakers too. This nets uptime over 99%. Clients in harsh spots—like desert pads—lean on it. As an electrical equipment supplier, SHENGTE logs every call. Patterns guide upgrades.

Availability of Parts & Repair Services: Stock matters most in a crunch. Choose suppliers with a long inventory of after-sales spare parts to ensure that casing, taps, and instruments are ready for shipment at any time. Repairs happen locally or back at plant. Field teams handle 80% on-site. This chain keeps custom transformers alive. It turns one-off buys into steady flows.

Delays can lead to project failures. Delayed delivery of power transformers stalled construction and caused costs to soar. In 2025, chip and steel shortages challenged supply chains. Astute transformer manufacturers plan ahead and budget carefully. SHENGTE maintains a comprehensive inventory and extensive supply chain. As a manufacturer of compact substations, we produce prefabricated components in phases to increase speed. Delivery determines speed. But true value comes from mutual trust. Partners share a common goal, building a shared future together.

On-Time Delivery and Production Capacity: Time is the cornerstone of trust. SHENGTE promises delivery dates, with a 90% delivery rate. Automation reduces manufacturing time—a standard ground-mounted transformer takes just 30 days. For substations, prefabrication reduces on-site work by 50%. Underground substations are plug-and-play. This process benefits buyers. No idle workers, only a stable power supply.

The Supplier as a Strategic Partner: Choosing the right supplier is half the battle. SHENGTE Power customizes transformers to meet grid needs according to customer specifications. Our OEM department allows you to brand your white-label power transformers. As a leading transformer supplier, we offer regular training to help you develop your skills. A long-term partnership with SHENGTE means opportunities at critical moments.

Selecting a transformer supplier ranks as a big strategic decision. Balance hits four pillars: quality through certs, technical via metrics and tweaks, support in fixes and parts, chains in flow and bonds. Miss one, and gaps show. Only by addressing these critical links can the power grid operate safely.

As we move towards 2025, rely on professionals. SHENGTE stands tall as a transformer and electrical equipment supplier. Our custom transformers, compact substations, and full lines match needs. From dry-type to underground transformer substations, quality holds. Contact us today at juanie@shengtetransformer.com for custom solutions.

content is empty!

content is empty!