- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-08-31 Origin: Site

Introduction

The role of transformers in modern electrical systems is vital, serving as the backbone of power distribution across the globe. Whether in residential areas, industrial zones, or large-scale infrastructure projects, transformers ensure that electrical energy is delivered efficiently, safely, and reliably. However, the selection of the right type of transformer is not a one-size-fits-all scenario. Various factors, including environmental conditions, load requirements, safety concerns, and maintenance capabilities, play critical roles in determining the most suitable transformer type for a given application.

One such crucial environmental factor is the operating climate, particularly in regions characterized by extreme cold temperatures. In such settings, the performance and reliability of electrical equipment can be significantly impacted. Among the types of transformers available—oil-immersed and dry-type—each has its advantages and disadvantages. However, in cold climates, dry-type transformers are increasingly favored over their oil-immersed counterparts due to several compelling reasons. This article explores these reasons in detail, examining the technical, environmental, and economic aspects that make dry-type transformers the superior choice in cold climates.

One of the most significant challenges for oil-immersed transformers in cold climates is the behavior of the insulating oil under low temperatures. Transformer oil serves as both a cooling medium and an insulator, crucial for maintaining the transformer's efficiency and safety. However, as temperatures drop, the viscosity of the oil increases. In extremely cold conditions, the oil can become excessively thick, which severely hampers its ability to flow and dissipate heat. This reduction in cooling efficiency can lead to overheating of the transformer, despite the cold ambient conditions, potentially causing thermal stress and reducing the lifespan of the transformer.

Moreover, in sub-zero temperatures, there is a risk that the transformer oil may begin to solidify or gel, especially if the oil contains moisture or impurities. This can result in blocked oil pathways, leading to inadequate cooling and uneven temperature distribution within the transformer. Such conditions not only degrade the performance of the transformer but also increase the risk of electrical faults, which can cause unplanned outages or even catastrophic failures.

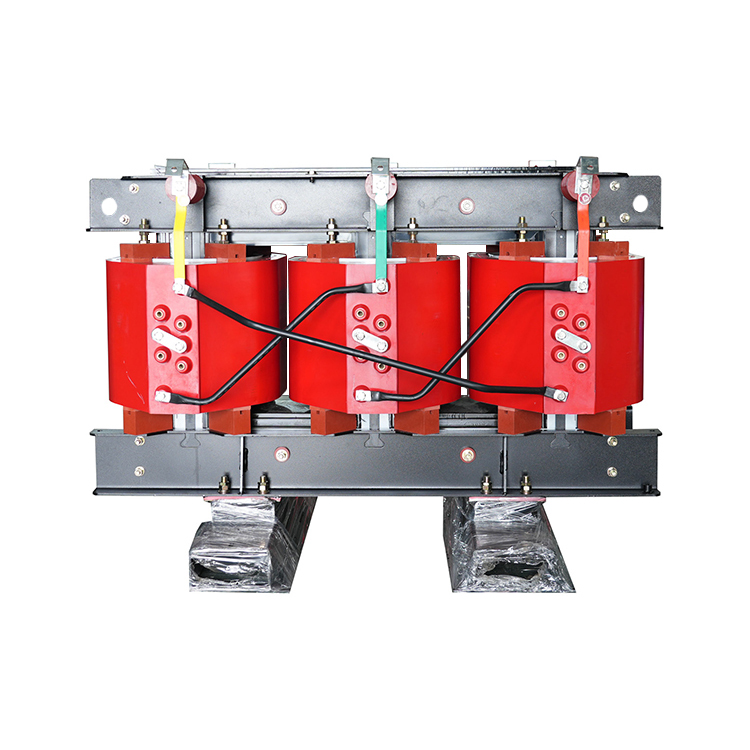

Dry-type transformers, on the other hand, do not rely on liquid insulation. Instead, they use solid insulation materials, such as epoxy resin, which are inherently more stable across a wide range of temperatures. These materials do not exhibit the same issues with viscosity or solidification as oil, ensuring consistent performance even in the harshest cold climates. The absence of oil eliminates the risk of the insulation medium becoming a performance bottleneck, allowing dry-type transformers to operate reliably without the concerns associated with oil-based systems.

Furthermore, the solid insulation in dry-type transformers offers superior mechanical stability, reducing the likelihood of cracks or damage due to thermal contraction and expansion. This stability is crucial in cold climates, where significant temperature fluctuations can occur, particularly between day and night or during sudden cold snaps. The robust design of dry-type transformers ensures that they can withstand these thermal stresses without compromising performance or safety.

Maintaining oil-immersed transformers involves several critical tasks, including regular oil testing, filtration, and replacement to ensure that the oil remains free of contaminants and retains its insulating properties. In cold climates, these maintenance activities become even more challenging. The viscosity of the oil at low temperatures makes handling, pumping, and processing the oil more difficult and time-consuming. Additionally, outdoor maintenance work in cold weather can be hazardous and may require specialized equipment and procedures to protect both the technicians and the transformer.

Another maintenance concern is the potential for moisture ingress in oil-immersed transformers. Cold climates often bring with them higher humidity levels, particularly during periods of snowmelt or frost. If moisture enters the transformer oil, it can significantly reduce the insulating properties of the oil, leading to increased risk of electrical breakdowns. This necessitates frequent monitoring and dehumidification, adding to the maintenance burden.

Dry-type transformers are inherently low-maintenance compared to oil-immersed transformers. Since they do not use oil, there is no need for oil testing, filtration, or replacement, eliminating many of the routine maintenance tasks associated with oil-immersed transformers. This not only reduces the operational costs but also minimizes the potential for human error during maintenance activities.

In cold climates, the maintenance advantages of dry-type transformers are particularly pronounced. The solid insulation used in these transformers is highly resistant to moisture, and there are no liquid components that can freeze or become viscous. This makes dry-type transformers much easier to maintain in cold environments, as they do not require the same level of attention or specialized procedures to ensure reliable operation.

Moreover, the robust construction of dry-type transformers means that they are less prone to mechanical damage from thermal cycling—an important consideration in regions where temperatures can vary widely throughout the year. The reduced need for maintenance, combined with the ability to operate reliably in cold conditions, makes dry-type transformers an ideal choice for remote or difficult-to-access locations, where maintenance activities are both costly and challenging.

One of the most significant environmental concerns with oil-immersed transformers is the potential for oil leaks. Transformer oil is typically a mineral-based product that can pose environmental hazards if it leaks into the surrounding soil or water sources. In cold climates, where the ground may be frozen for significant portions of the year, cleaning up oil spills can be particularly challenging. The oil can seep into the ground and remain trapped in frozen soil, making it difficult to remove and increasing the risk of long-term contamination.

Additionally, in the event of a catastrophic failure, oil-immersed transformers can release large quantities of oil, potentially leading to significant environmental damage. This risk is exacerbated in cold climates, where the response time for environmental remediation may be delayed due to weather conditions, further increasing the potential impact.

Dry-type transformers eliminate the risk of oil spills entirely, as they do not use oil as an insulating or cooling medium. This makes them a much more environmentally friendly option, particularly in ecologically sensitive areas or regions where environmental regulations are strict. In cold climates, where the potential for environmental damage from oil spills is heightened, dry-type transformers offer a safer and more sustainable alternative.

Furthermore, the materials used in dry-type transformers, such as epoxy resin, are generally non-toxic and can be more easily contained and managed in the event of a failure. This reduces the environmental impact of the transformer and aligns with the growing emphasis on sustainable and environmentally responsible practices in the power industry.

Another environmental consideration is the carbon footprint associated with transformer maintenance and operation. Dry-type transformers, with their lower maintenance requirements, generate less waste and require fewer resources over their operational lifetime. This contributes to a reduced environmental impact, making them an attractive choice for organizations committed to sustainability.

One of the key safety risks associated with oil-immersed transformers is the potential for fire and explosion. Transformer oil, while effective as an insulator and coolant, is also flammable. In the event of an electrical fault, such as a short circuit or an arc, the oil can ignite, leading to a fire or explosion. This risk is particularly concerning in cold climates, where extreme temperature variations can exacerbate the likelihood of electrical faults and where firefighting efforts may be hampered by weather conditions.

In addition to the risk of fire, the explosion of an oil-immersed transformer can have devastating consequences, not only causing significant damage to the transformer itself but also posing a serious threat to nearby infrastructure and personnel. The aftermath of such incidents can include extended power outages, costly repairs, and significant safety hazards, particularly in densely populated or industrial areas.

Dry-type transformers offer a much higher level of safety compared to oil-immersed transformers, primarily due to the absence of flammable materials. The solid insulation used in dry-type transformers is not only non-flammable but also highly resistant to electrical faults. This significantly reduces the risk of fire and explosion, making dry-type transformers a safer option, especially in environments where fire safety is a critical concern.

The enhanced safety profile of dry-type transformers is particularly advantageous in cold climates, where emergency response times may be slower due to adverse weather conditions. The reduced risk of fire and explosion not only protects the transformer itself but also enhances the overall safety of the installation site, whether it is a residential neighborhood, an industrial facility, or a remote power station.

In addition to fire safety, dry-type transformers also offer improved protection against electrical shocks and arc flashes. The solid insulation provides a high level of dielectric strength, ensuring that electrical faults are contained and do not pose a risk to personnel or equipment. This is especially important in environments where safety standards are stringent, and any potential risk to human life or critical infrastructure must be minimized.

Oil-immersed transformers require careful planning and installation, particularly in cold climates. The need for proper oil containment, fire suppression systems, and regular maintenance access adds to the complexity and cost of installation. Additionally, oil-immersed transformers are typically larger and heavier than their dry-type counterparts, which can pose logistical challenges during transportation and installation, especially in remote or difficult-to-access areas.

In cold climates, the installation of oil-immersed transformers may also require additional measures to prevent the oil from freezing or becoming too viscous during operation. This can include the installation of heating systems or the use of special insulating materials, both of which increase the overall cost and complexity of the project.

Dry-type transformers, by contrast, offer significant advantages in terms of installation flexibility and cost. Their compact and modular design allows for easier transportation and installation, even in challenging environments. Because they do not require oil containment or fire suppression systems, dry-type transformers can be installed in a wider range of locations, including indoor spaces, underground vaults, and other confined areas.

The absence of oil also simplifies the installation process, as there is no need for additional infrastructure to manage and monitor the oil. This reduces both the upfront capital costs and the ongoing operational expenses associated with the transformer. In cold climates, where installation and maintenance can be particularly challenging and expensive, the cost savings associated with dry-type transformers can be substantial.

Furthermore, the ease of installation and reduced maintenance requirements of dry-type transformers can result in shorter project timelines, allowing for faster deployment of electrical infrastructure. This is particularly beneficial in areas with rapidly growing energy demands or in emergency situations where a quick response is needed to restore power.

While oil-immersed transformers may have a lower initial purchase price compared to dry-type transformers, the total cost of ownership over the transformer's lifespan can be significantly higher. This is due to the ongoing maintenance requirements, the need for regular oil testing and replacement, and the potential costs associated with environmental compliance and risk mitigation.

In cold climates, these costs can be further amplified by the challenges of maintaining and operating oil-immersed transformers in sub-zero temperatures. The need for additional heating systems, insulation, and specialized maintenance procedures can add to the operational expenses, making oil-immersed transformers a less economically viable option in the long run.

Additionally, the potential for unplanned outages or equipment failures due to oil-related issues can result in costly downtime and repairs. In industries where continuous power supply is critical, such as manufacturing, healthcare, or data centers, the economic impact of transformer failures can be significant.

Dry-type transformers, while generally more expensive upfront, offer better long-term economic efficiency. Their low maintenance requirements, combined with the absence of oil-related risks and the need for fewer ancillary systems, result in lower operating costs over the transformer's lifetime. This makes dry-type transformers a more cost-effective solution, particularly in cold climates where maintenance and operational challenges are more pronounced.

The enhanced reliability of dry-type transformers also contributes to their long-term efficiency. With fewer components that can fail and a design that is inherently more robust in cold environments, dry-type transformers are less likely to experience downtime or require costly repairs. This reliability translates into higher uptime and greater operational continuity, which is especially valuable in industries where even short interruptions in power supply can have significant economic repercussions.

Moreover, the longer lifespan of dry-type transformers, due to their resistance to thermal stress and environmental degradation, further enhances their economic appeal. By reducing the frequency of replacements and minimizing the need for extensive maintenance, dry-type transformers offer a superior return on investment, particularly in regions with challenging environmental conditions.

In conclusion, the choice between oil-immersed and dry-type transformers is influenced by a range of factors, including technical performance, maintenance requirements, environmental impact, safety considerations, installation flexibility, and economic efficiency. In cold climates, these factors collectively make dry-type transformers the superior choice.

The technical advantages of dry-type transformers, including their stable performance in low temperatures and resistance to thermal stress, ensure reliable operation even in the harshest conditions. Their low maintenance requirements and reduced environmental impact further enhance their suitability for cold climates, where traditional oil-immersed transformers may struggle to perform effectively.

Safety is another critical consideration, with dry-type transformers offering a much lower risk of fire, explosion, and electrical faults compared to oil-immersed transformers. This makes them a safer option for both personnel and infrastructure, particularly in environments where emergency response capabilities may be limited by weather conditions.

Finally, the economic benefits of dry-type transformers, including lower long-term costs and higher operational efficiency, make them an attractive investment for organizations seeking reliable and sustainable power solutions in cold climates.

As the demand for reliable and efficient power distribution continues to grow, particularly in regions with extreme weather conditions, the advantages of dry-type transformers will likely become even more pronounced. By offering a safer, more sustainable, and cost-effective solution, dry-type transformers are well-positioned to meet the evolving needs of the global power industry, ensuring that electricity is delivered safely and efficiently, regardless of the climate.

content is empty!

content is empty!