- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

Technical Differences Between Power and Distribution Transformers

Factors to Consider When Choosing Between Power and Distribution Transformers

In today's world of electrical systems, transformers are super important for moving electricity safely and smoothly from where it’s made to where it’s used. Knowing the difference between power transformers and distribution type transformers is key to making sure everything works well and stays dependable. This piece dives into how they differ in what they do, how they’re built, and where they’re used, helping folks make smart choices for planning power systems.

To understand how electricity reaches our homes and businesses efficiently, let’s explore the key roles and features of electrical transformers.

An electrical transformer is a handy device that shifts electric power between circuits using electromagnetic induction. It can boost or reduce voltage as required. This helps send power over long distances effectively and saves energy.

Transformers have primary and secondary coils wrapped around a magnetic core. Current flows through the primary coil. This makes a magnetic field. The field then creates voltage in the secondary coil. The number of loops in each coil decides if voltage increases or decreases.

Transformers are a big deal in any power setup. They help send high-voltage power from where it’s made over huge distances with very little loss. Then, they lower the voltage so it’s safe to use in homes, offices, or factories.

Power transformers are built for heavy-duty jobs, often used in transmission to manage large amounts of electric power.

These transformers usually work with voltages over 33kV. They can handle power from a few hundred kVA up to hundreds of MVA. Their main job is to boost voltage at power plants or lower it at substations before it gets sent out.

You’ll find power transformers at places where electricity is made. They increase the voltage from turbines so it can travel long distances without losing much energy.

They’re also placed in substations along major power lines. Here, they reduce the voltage for the next step of distribution.

These machines are designed to work best when fully loaded. They run all the time and need to handle a lot of heat without breaking down or losing performance.

On the other hand, distribution type transformers are the last step in changing voltage before power reaches the people who use it.

These transformers take medium-voltage power, like 11kV or 6.6kV, and bring it down to levels like 400V or 230V. That’s the kind of voltage safe for homes or small businesses.

To see how distribution type transformers are integrated into power systems, let’s examine their typical placements and applications.

You often see these units on poles along streets or in boxed setups on the ground called pad-mounted transformers. These, sometimes called American Box Transformers or combined transformers, are crucial for cable-based power networks.

Distribution type transformers are often seen in neighborhoods, stores, hospitals, factories, airports, and other places. They are small and simple to install. This makes them very useful. Pad-mounted transformers look like small boxes. They are light, quiet, save energy, and work well for a long time.

Distribution type transformers handle power changes during the day. The amount of power people use keeps changing. So, these transformers are built to work nicely even when not fully used. Power transformers, however, always run at full power.

Looking at the tech details helps show how these two kinds of transformers aren’t the same.

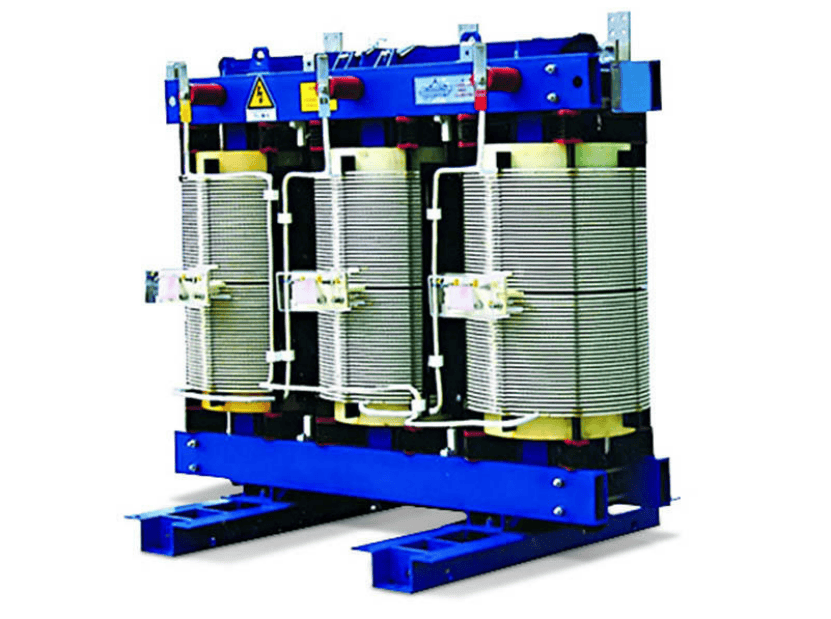

Power transformers have tough insulation to deal with high voltages. Meanwhile, distribution transformers often use dry-type builds for safety in busy areas. Dry-type transformers use special materials to keep current separate and avoid sparks. SHENGTE epoxy resin dry-type transformers stand out with great efficiency, low energy waste, quiet running, and awesome heat control.

Power transformers keep going at almost full capacity because they handle big transmission jobs. Distribution ones, though, deal with on-and-off loads depending on what users need at different times of day.

While both types often use oil for cooling, many distribution models in indoor or sensitive spots use dry-type cooling with air fans. This setup resists fire and doesn’t pollute. It’s safer and can be placed right where the power is needed.

Picking the right type of transformer, whether power or distribution, makes a huge difference in how well the network runs.

Choosing a transformer that fits its job cuts down on energy waste. For example, epoxy resin cast dry transformers are safe to run, resist flames, and don’t harm the environment. They lose little power and can handle 120% of their rated load with forced air cooling.

At first, the price might not differ much based on size needs. But over time, how efficient they are matters more. Better efficiency means less energy loss and lower upkeep costs, saving money in the long run.

Dry-type distribution models need almost no upkeep, which is perfect for city setups. Oil-cooled power units might need regular checks but last longer when loads stay steady.

The choice of transformer often depends on what a specific industry needs for power.

Factories with big machines or motors usually go for power transformers. These can handle heavy loads well for long stretches of time.

In cities, small pad-mounted distribution units are popular since they fit in without needing extra space for substations. They keep people safe and don’t require separate power rooms. In rural spots, pole-mounted ones are often used because of limited space.

Both kinds can work with solar or wind farms. It depends on where the voltage change happens—either boosting it from the source with power transformers or lowering it near users with distribution ones.

A bunch of tech factors play a role in picking the best transformer for a project.

High-voltage setups need the strong insulation of power models. Lower-voltage systems do better with the flexible setup options of distribution designs.

If a project will have steady, heavy loads, power models are the way to go. For places with changing demand, like homes, distribution units are better since they adjust to varying conditions.

For indoor spots near buildings with people, dry-type, fireproof models like epoxy resin cast ones are safer. They’re simple to set up, need no upkeep, and cost less to run overall.

With many years of know-how in providing solid energy solutions worldwide:

SHENGTE has become a top name in creating advanced electrical gear. They focus on meeting needs for projects like city infrastructure upgrades.

Their wide range of products includes dry-type transformers, ready-made substations, underground combined setups, and electrical switchgear systems. All meet global rules like IEC1330 to ensure they work great in many uses.

SHENGTE’s gear comes with smart features like auto temperature checks, fireproof covers, and overload safety tools. These boost reliability and cut down on harm to the environment. Their transformers have intelligent temperature controllers to keep things safe while running.

Deciding between a power transformer and a distribution type transformer hinges on your project’s voltage needs, how loads will behave over time, and space limits. This choice affects how much energy you save over many years of use. Matching the right type to the job ensures the grid runs smoothly and cuts risks of breakdowns or inefficiencies. With low upkeep needs, these units meet top global reliability standards based on real-world tests.

Q1: What is the main difference between a power transformer and a distribution transformer?

A: A power transformer works with higher voltages, over 33kV, and runs at full capacity all the time in transmission setups. A distribution transformer, though, lowers medium voltages like 11kV for users in homes or businesses, handling changing loads.

Q2: Can a distribution transformer be used in place of a power transformer?

A: Usually not. Distribution transformers aren’t made for constant heavy loads like in transmission systems. Using them wrong could cause overheating or breakdowns since they lack the right insulation or cooling power.

Q3: How do I figure out which transformer type fits my project?

A: Start by checking your system’s voltage needs. Then think about load patterns—steady or changing. Consider the spot, whether inside or outside, safety rules like fireproofing, and upkeep options. Talk to pros like SHENGTE for advice on solutions that follow global standards.

content is empty!

content is empty!