- All

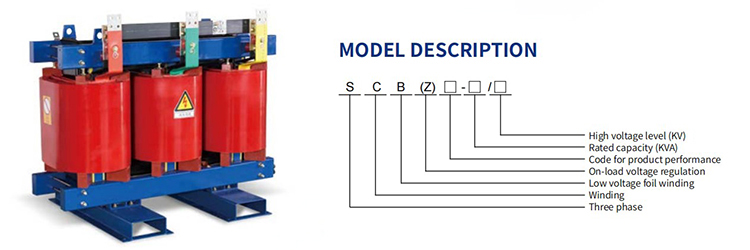

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SCB10-630/6

SHENGTE

| Availability: | |

|---|---|

| Quantity: | |

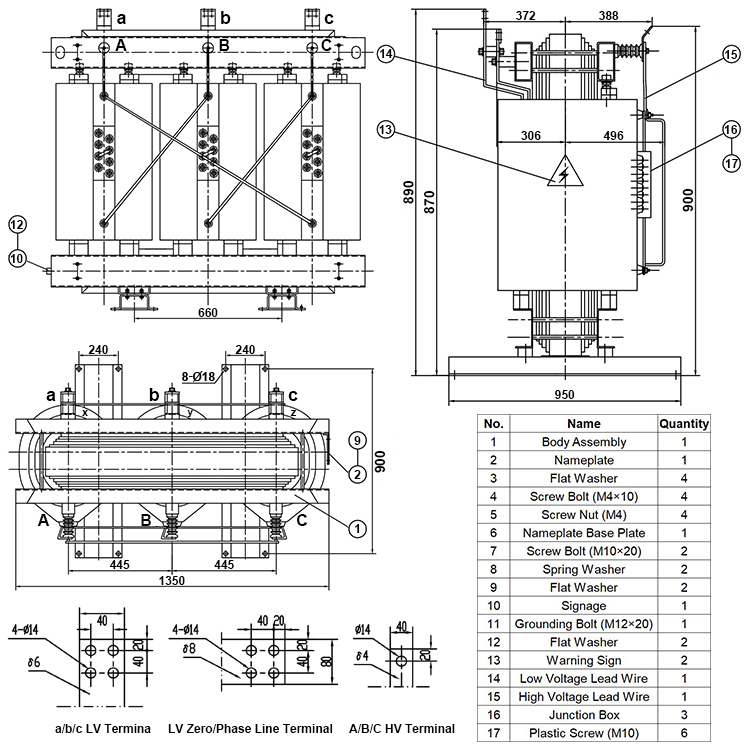

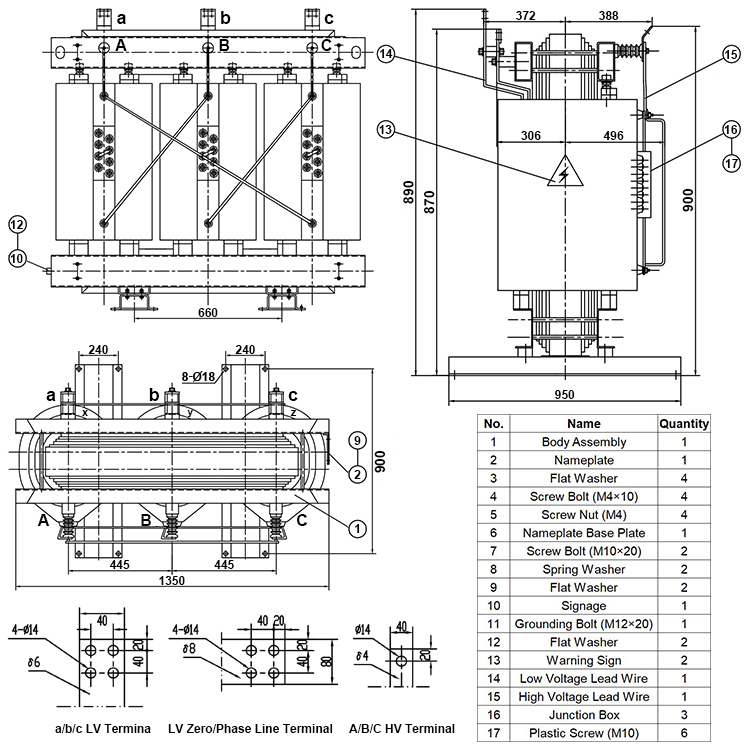

Dry-type transformers, including 3-phase dry-type transformers and cast resin dry-type transformers, use advanced insulation materials that protect against current leakage and electrical arcs. Unlike traditional oil-filled units, SHENGTE dry power transformers keep their cores and windings completely dry — no messy oil baths, no risk of leaks. You can choose natural or forced air cooling depending on the site. Dry cast resin transformers are suitable for indoor installations like schools, hospitals, and data centers. The insulation material of SHENGTE 3-phase dry-type transformer handles high heat and electrical stress, so you don’t need to worry about extra upkeep.

Features:

High-Voltage Winding Strength: The SHENGTE 3-phase dry-type transformer’s HV winding is vacuum cast with epoxy resin mixed with fillers, giving it low partial discharge and very high electrical strength. Both the inner and outer walls are reinforced with glass fiber mesh plates — that extra reinforcement makes the coil tougher and better able to withstand sudden short circuits without shifting.

Low-Voltage Foil Winding: Instead of traditional wire winding, the SHENGTE 3-phase dry power transformer’s LV side uses a foil structure. This design avoids the spiral angle issue, so the ampere-turn distribution is more balanced. Axial cooling ducts are built right into the coil, improving heat dissipation, while layers are bonded with DMD epoxy resin cloth, cured into one solid body.

Efficient Iron Core: Built from cold-rolled silicon steel sheets, the core of this dry-type distribution transformer uses a three-step full-mitered joint design. The columns are strapped with F-class bands and coated in epoxy resin. This setup cuts down on no-load loss, no-load current, and even trims noise from the core. Clamps and fasteners are surface-treated, too, which not only boosts durability but also gives the unit a cleaner finish.

Cooling Fan System: A cross-flow top-blowing fan is fitted to this dry cast resin transformer. It runs quietly, provides strong air pressure, and — small detail — the compact fan design even looks neat. More importantly, it gives the dry power transformer extra overload capacity when needed.

Intelligent Temperature Control: Each dry cast resin transformer comes with a smart temperature controller. It constantly monitors coil temperature, stepping in to prevent overheating, which raises both operational safety and reliability.

Protective Casing Options: The SHENGTE 3-phase dry-type transformer can be housed in enclosures with protection levels like IP20, IP23, IP30, or IP33. Depending on the environment, the casing can be aluminum alloy, cold-rolled steel plate, or stainless steel. This means extra safety and flexibility for indoor and outdoor projects alike.

Our Advantages:

High Efficiency with Low Losses: This 3-phase dry-type transformer runs with very low operational losses, low noise, and almost no partial discharge. With forced air cooling, it can safely carry up to 120% load.

Moisture Resistance: Unlike oil-filled units, this cast resin dry-type transformer works even in 100% humidity. It doesn’t need drying before restarting after a shutdown, which makes it ideal for coastal or tropical regions.

Safety: As a dry power transformer, it’s fire-resistant and free from oil leaks. That makes it safer to install indoors, in places like schools, hospitals, or office buildings. No need to worry about fire hazards or pollution — a big plus in modern urban projects.

Temperature Control and Protection: This 3-phase dry-type transformer includes a smart monitoring system that tracks coil temperature. If things heat up, it reacts quickly to prevent damage.

Easy Installation and Low Maintenance: Being a dry-type distribution transformer, setup is straightforward, and it hardly needs maintenance. No oil checks, no leaks, no messy cleanups. On a real job site, this can save days of work and cut operating costs for years.

Proven Reliability: This resin casting transformer meets strict international standards, and field tests have shown excellent durability.

Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| SCB10-30 | 30 | 6 6.3 6.6 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 190 | 710 | 2 | 4 |

SCB10-50 | 50 | 270 | 1000 | 2 | 4 | ||||

SCB10-80 | 80 | 370 | 1380 | 1.5 | 4 | ||||

SCB10-100 | 100 | 400 | 1570 | 1.5 | 4 | ||||

SCB10-125 | 125 | 470 | 1850 | 1.3 | 4 | ||||

SCB10-160 | 160 | 540 | 2130 | 1.3 | 4 | ||||

SCB10-200 | 200 | 620 | 2530 | 1.1 | 4 | ||||

SCB10-250 | 250 | 720 | 2760 | 1.1 | 4 | ||||

SCB10-315 | 315 | 880 | 3470 | 1 | 4 | ||||

SCB10-400 | 400 | 980 | 3990 | 1 | 4 | ||||

SCB10-500 | 500 | 1160 | 4880 | 1 | 4 | ||||

| SCB10-630 | 630 | 1300 | 5960 | 0.85 | 6 | ||||

SCB10-800 | 800 | 1520 | 6960 | 0.85 | 6 | ||||

SCB10-1000 | 1000 | 1770 | 8130 | 0.85 | 6 | ||||

SCB10-1250 | 1250 | 2090 | 9690 | 0.85 | 6 | ||||

SCB10-1600 | 1600 | 2450 | 11700 | 0.85 | 6 | ||||

SCB10-2000 | 2000 | 3050 | 14400 | 0.7 | 6 | ||||

| SCB10-2500 | 2500 | 3600 | 17100 | 0.7 | 6 | ||||

Q1: What’s special about this 3-phase dry-type transformer compared to an oil unit?

A1: No oil, no leaks, no mess. A cast resin dry-type transformer uses solid insulation instead of oil, so it’s safer in places like hospitals or underground buildings.

Q2: How reliable is this 3-phase dry power transformer in tough environments?

A2: Pretty solid. These dry cast resin transformers keep running even in 100% humidity. In coastal projects we’ve done, units stayed in service for years without issues, except for the usual dust wipe-down. They don’t need “drying out” after shutdown, which is a relief for maintenance teams.

Q3: Do you offer custom designs or just standard models?

A3: Both. Our factory has produced thousands of dry-type distribution transformers, and we often tweak specs — voltage, connection group, casing — to match project needs.

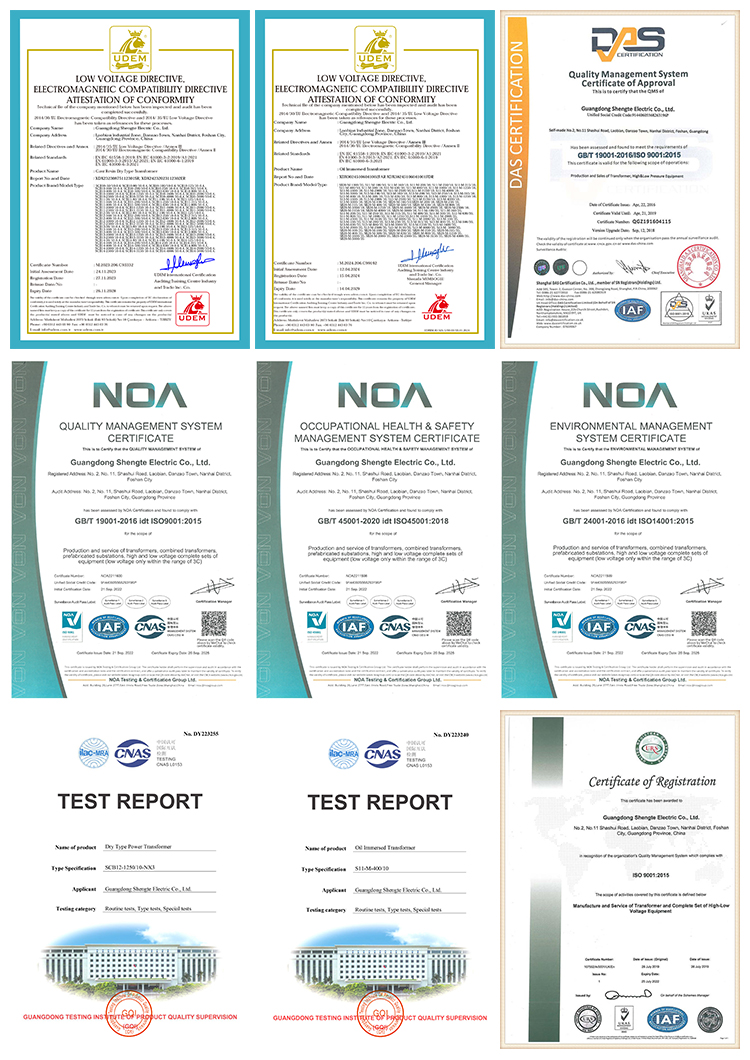

Q4: How about certifications and test reports?

A4: Yes, every unit comes with full test data. We’ve got ISO9001 and CE, and can provide reports according to IEC standards. It’s part of why buyers trust our dry power transformers for public projects where paperwork is as important as performance.

Q5: What’s the usual delivery time and MOQ?

A5: Delivery is normally 20–30 days, though smaller jobs can be quicker. And MOQ? Just 1 set.

Q6: Do you provide after-sales service?

A6: Definitely. Warranty is 12 months, but honestly, issues are rare. If there’s ever a problem with our dry cast resin transformers or other products, our team works with local partners or sends engineers to the site.

Dry-type transformers, including 3-phase dry-type transformers and cast resin dry-type transformers, use advanced insulation materials that protect against current leakage and electrical arcs. Unlike traditional oil-filled units, SHENGTE dry power transformers keep their cores and windings completely dry — no messy oil baths, no risk of leaks. You can choose natural or forced air cooling depending on the site. Dry cast resin transformers are suitable for indoor installations like schools, hospitals, and data centers. The insulation material of SHENGTE 3-phase dry-type transformer handles high heat and electrical stress, so you don’t need to worry about extra upkeep.

Features:

High-Voltage Winding Strength: The SHENGTE 3-phase dry-type transformer’s HV winding is vacuum cast with epoxy resin mixed with fillers, giving it low partial discharge and very high electrical strength. Both the inner and outer walls are reinforced with glass fiber mesh plates — that extra reinforcement makes the coil tougher and better able to withstand sudden short circuits without shifting.

Low-Voltage Foil Winding: Instead of traditional wire winding, the SHENGTE 3-phase dry power transformer’s LV side uses a foil structure. This design avoids the spiral angle issue, so the ampere-turn distribution is more balanced. Axial cooling ducts are built right into the coil, improving heat dissipation, while layers are bonded with DMD epoxy resin cloth, cured into one solid body.

Efficient Iron Core: Built from cold-rolled silicon steel sheets, the core of this dry-type distribution transformer uses a three-step full-mitered joint design. The columns are strapped with F-class bands and coated in epoxy resin. This setup cuts down on no-load loss, no-load current, and even trims noise from the core. Clamps and fasteners are surface-treated, too, which not only boosts durability but also gives the unit a cleaner finish.

Cooling Fan System: A cross-flow top-blowing fan is fitted to this dry cast resin transformer. It runs quietly, provides strong air pressure, and — small detail — the compact fan design even looks neat. More importantly, it gives the dry power transformer extra overload capacity when needed.

Intelligent Temperature Control: Each dry cast resin transformer comes with a smart temperature controller. It constantly monitors coil temperature, stepping in to prevent overheating, which raises both operational safety and reliability.

Protective Casing Options: The SHENGTE 3-phase dry-type transformer can be housed in enclosures with protection levels like IP20, IP23, IP30, or IP33. Depending on the environment, the casing can be aluminum alloy, cold-rolled steel plate, or stainless steel. This means extra safety and flexibility for indoor and outdoor projects alike.

Our Advantages:

High Efficiency with Low Losses: This 3-phase dry-type transformer runs with very low operational losses, low noise, and almost no partial discharge. With forced air cooling, it can safely carry up to 120% load.

Moisture Resistance: Unlike oil-filled units, this cast resin dry-type transformer works even in 100% humidity. It doesn’t need drying before restarting after a shutdown, which makes it ideal for coastal or tropical regions.

Safety: As a dry power transformer, it’s fire-resistant and free from oil leaks. That makes it safer to install indoors, in places like schools, hospitals, or office buildings. No need to worry about fire hazards or pollution — a big plus in modern urban projects.

Temperature Control and Protection: This 3-phase dry-type transformer includes a smart monitoring system that tracks coil temperature. If things heat up, it reacts quickly to prevent damage.

Easy Installation and Low Maintenance: Being a dry-type distribution transformer, setup is straightforward, and it hardly needs maintenance. No oil checks, no leaks, no messy cleanups. On a real job site, this can save days of work and cut operating costs for years.

Proven Reliability: This resin casting transformer meets strict international standards, and field tests have shown excellent durability.

Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| SCB10-30 | 30 | 6 6.3 6.6 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 190 | 710 | 2 | 4 |

SCB10-50 | 50 | 270 | 1000 | 2 | 4 | ||||

SCB10-80 | 80 | 370 | 1380 | 1.5 | 4 | ||||

SCB10-100 | 100 | 400 | 1570 | 1.5 | 4 | ||||

SCB10-125 | 125 | 470 | 1850 | 1.3 | 4 | ||||

SCB10-160 | 160 | 540 | 2130 | 1.3 | 4 | ||||

SCB10-200 | 200 | 620 | 2530 | 1.1 | 4 | ||||

SCB10-250 | 250 | 720 | 2760 | 1.1 | 4 | ||||

SCB10-315 | 315 | 880 | 3470 | 1 | 4 | ||||

SCB10-400 | 400 | 980 | 3990 | 1 | 4 | ||||

SCB10-500 | 500 | 1160 | 4880 | 1 | 4 | ||||

| SCB10-630 | 630 | 1300 | 5960 | 0.85 | 6 | ||||

SCB10-800 | 800 | 1520 | 6960 | 0.85 | 6 | ||||

SCB10-1000 | 1000 | 1770 | 8130 | 0.85 | 6 | ||||

SCB10-1250 | 1250 | 2090 | 9690 | 0.85 | 6 | ||||

SCB10-1600 | 1600 | 2450 | 11700 | 0.85 | 6 | ||||

SCB10-2000 | 2000 | 3050 | 14400 | 0.7 | 6 | ||||

| SCB10-2500 | 2500 | 3600 | 17100 | 0.7 | 6 | ||||

Q1: What’s special about this 3-phase dry-type transformer compared to an oil unit?

A1: No oil, no leaks, no mess. A cast resin dry-type transformer uses solid insulation instead of oil, so it’s safer in places like hospitals or underground buildings.

Q2: How reliable is this 3-phase dry power transformer in tough environments?

A2: Pretty solid. These dry cast resin transformers keep running even in 100% humidity. In coastal projects we’ve done, units stayed in service for years without issues, except for the usual dust wipe-down. They don’t need “drying out” after shutdown, which is a relief for maintenance teams.

Q3: Do you offer custom designs or just standard models?

A3: Both. Our factory has produced thousands of dry-type distribution transformers, and we often tweak specs — voltage, connection group, casing — to match project needs.

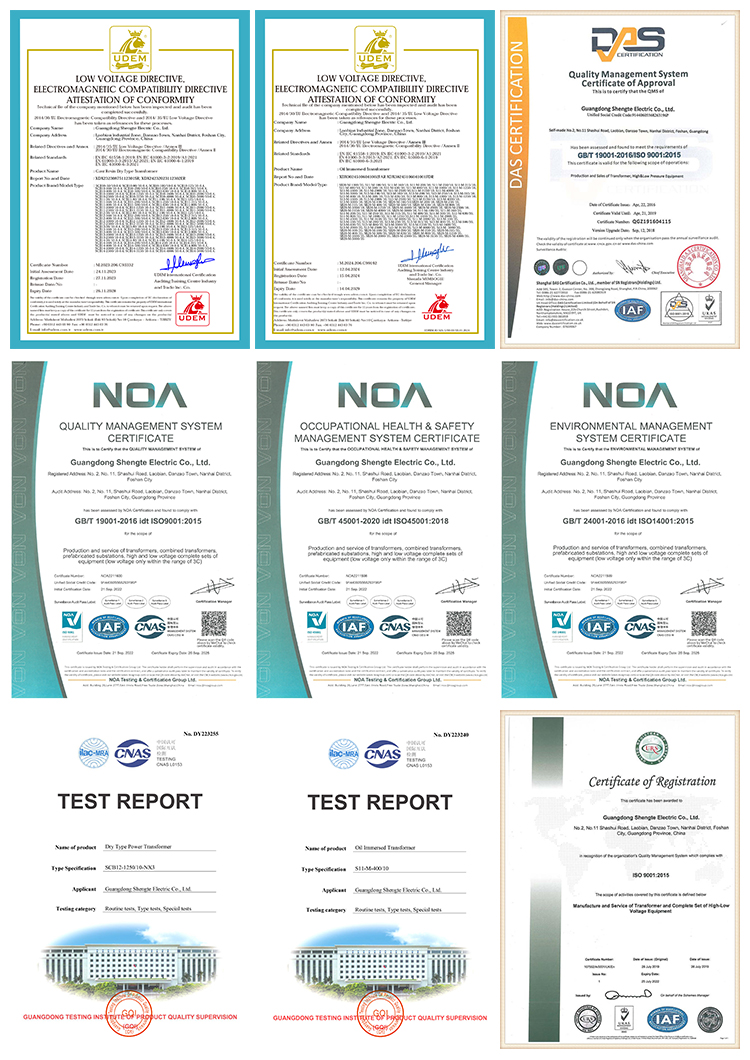

Q4: How about certifications and test reports?

A4: Yes, every unit comes with full test data. We’ve got ISO9001 and CE, and can provide reports according to IEC standards. It’s part of why buyers trust our dry power transformers for public projects where paperwork is as important as performance.

Q5: What’s the usual delivery time and MOQ?

A5: Delivery is normally 20–30 days, though smaller jobs can be quicker. And MOQ? Just 1 set.

Q6: Do you provide after-sales service?

A6: Definitely. Warranty is 12 months, but honestly, issues are rare. If there’s ever a problem with our dry cast resin transformers or other products, our team works with local partners or sends engineers to the site.

Analysis and Solution for The Failure of 35kV Dry-Type Transformer Lightning Impulse Test

Why Dry-Type Transformers Are Superior to Oil-Immersed Transformers in Cold Climates

How to Choose The Ideal Transformer Quantity and Capacity for Maximum Efficiency

Analysis of Causes of Failure in High-Voltage Foil-Wound Dry-Type Transformers

Maintenance Requirements for Dry Type and Oil-Immersed Transformers