- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-30 Origin: Site

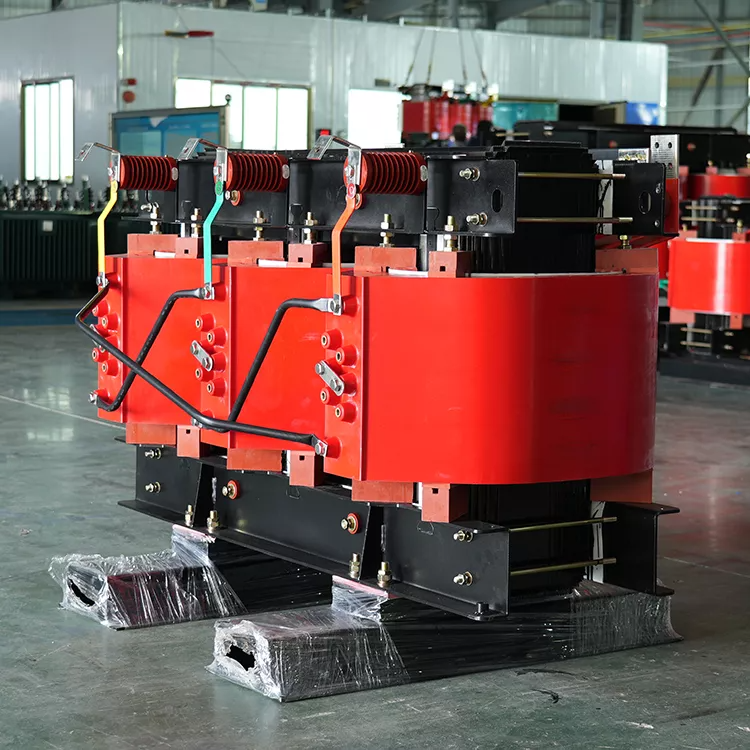

If you’re in charge of keeping the lights on in vital places like hospitals, data hubs, or factory control rooms, picking the right gear is a big deal. Safety, dependability, and smooth operation are non-negotiable. That’s where a dry-type distribution transformer comes in. Unlike the old-school oil-filled ones, these units are much safer from fire risks, need less upkeep, and are perfect for indoor spots.

This write-up dives into what makes dry-type transformers special. It also shows why they’re a must-have for important setups. Plus, we’ll take a closer look at how the SC(B)10 series from SHENGTE stands out with top-notch quality and value.

Dry-type transformers are often the go-to pick in places where safety and trust can’t be messed with. Their build cuts out any chance of oil spills or dangerous fires.

The strength of a dry-type distribution transformer comes from its tough materials and how its wires are set up. The high-voltage part is made using a vacuum process with epoxy resin mixed with special stuff. This keeps electric leaks low and makes the coil super strong. No oil is needed for cooling, thanks to this solid setup.

The inside and outside of the winding have glass fiber sheets for extra support. This boosts the coil’s toughness and helps the transformer handle sudden power spikes. On top of that, the low-voltage part uses a foil design. This fixes balance problems that often pop up in older wire setups.

Cooling happens with either natural airflow or fans pushing air around. These transformers don’t lose much power, keep electric leaks tiny, stay quiet, and spread heat well. With forced air, they can even handle 120% of their normal load. The epoxy resin keeps things steady under heat and blocks out dampness.

This is great for wet places where other transformers might need drying out after being turned off. These units can work in full humidity and start right back up without any extra steps.

In high-stakes spots where there’s no room for downtime, dry-type transformers bring benefits that oil-filled ones just can’t match.

Dry-type units cut out the fire dangers tied to oily liquids. They’re built to resist flames and don’t pollute. This means they can run safely and sit right in busy areas without needing special barriers. You can place them near delicate gear with no worries.

These transformers are made to manage heavy loads without breaking a sweat. The SHENGTE epoxy resin dry-type models work with great efficiency. They lose little power, make hardly any noise, and handle heat like champs. With fan cooling, they can take on a 120% load and still keep going. Even under tough heat or stress, they stay steady and deliver power without a hitch.

Unlike oil systems that might leak or blow up, dry-type transformers are free from those risks. The epoxy resin build makes them safe to run, hard to burn, and fireproof. They don’t cause messes either. This is a huge plus in places like hospitals or food factories where keeping things clean matters a lot.

Putting in a dry-type distribution transformer is pretty easy. Plus, they don’t need much care, which makes them a smart pick for today’s building projects.

These models don’t take up much room, but they do need good air around them to stay cool. They come with protective covers rated from IP20 to IP33, made of sturdy aluminum or steel. These cases add an extra layer of safety for the transformer. So, you can fit them into tight spots without a problem.

One awesome thing about them is how little work they need. Setting them up is a breeze, and they’re basically maintenance-free. This means they last longer and cost less to run over time. A quick look now and then is usually enough, unlike oil units that need constant checks on fluids or special tests.

In quiet indoor spots like medical centers or computer rooms, noise can be a big issue. These transformers keep sound low, between 43 and 50 DB(A), based on their size. That’s quiet enough for calm places. At the same time, they turn energy efficiently, so nothing goes to waste.

Important buildings have to follow strict rules for electric safety. Dry-type transformers are built to meet those tough demands.

These units stick to worldwide rules like IEC 60076-11 for heat ratings and IEEE C57 for how well they work. This means they’re good to go for local laws and global standards, no matter where you are. Their flame-proof design fits NFPA rules for indoor use. You don’t need extra fire gear around them. This is handy when planning small electric rooms or updating older buildings.

Dry-type distribution transformers are super flexible. They work well in many areas where steady power is everything.

In tech hubs where being online means money, the SC(B)10 series keeps voltage steady at ±5% or ±2×2.5%. They come in sizes from 30KVA to 2500KVA. Power loss when idle is low, between 190 and 3600 W, depending on the model. This keeps energy waste small, even when they’re not fully loaded.

With no chance of oil drips or harmful fumes, these transformers are safer to use. They’re super reliable and need no upkeep. This makes them ideal near sensitive spots like surgery rooms or scanning areas where clean air and steady power are a must.

In rough settings with power jumps or short circuits, these units hold up well. Their iron core, made from top-grade cold-rolled silicon steel sheets, stands strong against bumps. It also keeps magnetic power steady, even when loads change a lot.

When you’re looking for a supplier you can count on for key setups, SHENGTE shines as a top name in well-made dry-type transformers. They’ve got years of know-how in building every piece.

SHENGTE keeps a tight watch on quality at every step. They make sure each part—placing, securing, and joining coils—is spot-on. Wires are shielded just as the plans say. Their SC(B)10 series is crafted for tough spots like medical centers or plants. These units have proven themselves in thousands of setups all over the world.

Whether you’re swapping out old gear or starting fresh, their products grow with your needs. They’re steady, safe, and meet every rule in the book without cutting corners.

Using a dry-type distribution transformer isn’t just about the tech details. It’s about keeping things running strong while making your money go further over time.

You can relax knowing your power setup will keep working safely, even during heavy loads or harsh conditions. There’s no need to keep checking fluids or watching it all the time. Smart heat protection keeps things safe and steady. This makes them a wise pick for places that can’t afford to stop, no matter what.

With almost no upkeep costs and strong fire safety, these epoxy resin units are easy to set up and cheap to run overall. They don’t just perform well—they also cut losses from downtime as the years go by. That’s real value when every minute counts.

Q1: What makes dry-type distribution transformers suitable for indoor use?

A: Their sealed epoxy resin setup gets rid of risky liquids completely. They resist fire and don’t pollute. This makes them perfect for crowded or people-heavy spots like clinics or workplaces, without needing special safety zones.

Q2: How does a dry-type transformer compare to oil-immersed models in maintenance?

A: Dry-types need almost no regular care. They’re simple to put in and maintenance-free. Oil units, on the other hand, call for frequent fluid checks or leak watches. This saves you both time and extra costs.

Q3: Are dry-type distribution transformers energy efficient?

A: Yes, for sure. SHENGTE epoxy resin dry-type transformers work with awesome efficiency and lose very little power. They can even handle up to 120% load, which makes them great for times when demand spikes high.

content is empty!

content is empty!