- All

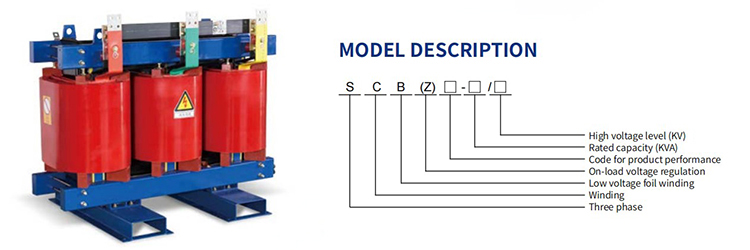

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SCB10-315/6

SHENGTE

| Availability: | |

|---|---|

| Quantity: | |

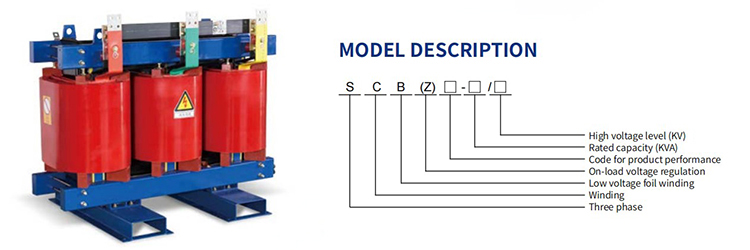

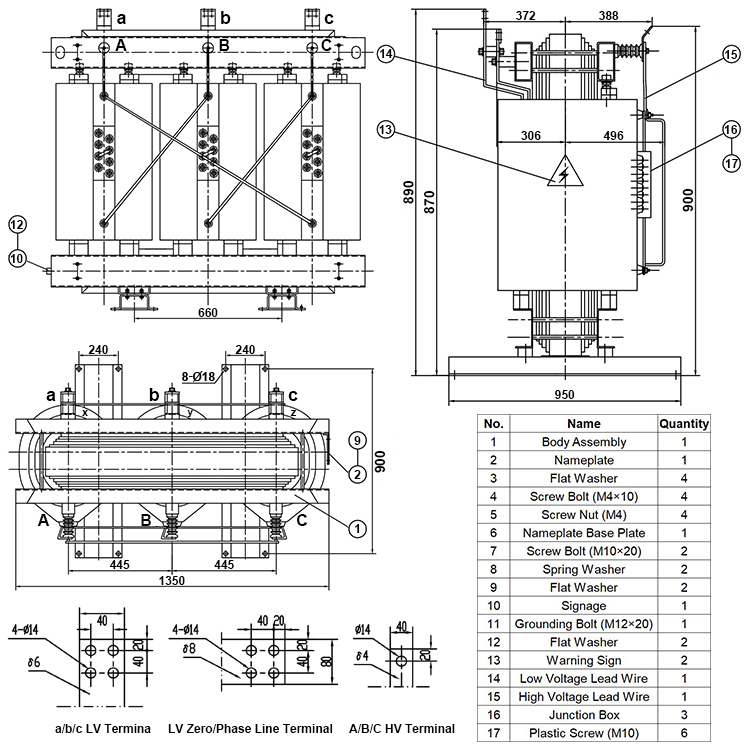

Dry type transformer adopts the special insulation materials to isolate current and prevent arcing, its iron core and winding are not immersed in the insulating oil, the cooling methods are divided into natural air cooling and forced air cooling. It is safer in operation, higher reliability and maintenance free.

The dry-type transformer utilizes unique insulation materials to isolate current and prevent arcing. Unlike traditional transformers, its iron core and winding remain unimmersed in insulating oil. Cooling methods are divided into natural air cooling and forced air cooling. This design ensures safer operation, increased reliability, and maintenance-free performance.

Features:

1. Exceptional Efficiency: Low operational losses, minimal noise, and limited partial discharge. The superior heat dissipation allows for operation at 120% of the rated load with forced air cooling.

2. Robust Moisture Resistance: Can operate in up to 100% humidity, with the capability to resume operation post-shutdown without the need for pre-drying.

3. Safety and Environmental Compliance: Fire-resistant and pollution-free, seamlessly integrated within load centers, enhancing operational safety.

4. Advanced Temperature Control: A sophisticated temperature protection system is in place to ensure the transformer's reliability and safe operation.

5. Low Maintenance and Easy Installation: Designed for hassle-free installation and maintenance-free operation, leading to reduced total operational costs.

6. Proven Reliability: Operational studies of units in the field indicate that the transformer's reliability aligns with the highest international standards.

Our Advantages:

1. The high-voltage winding is vacuum cast with epoxy resin filled with fillers, with low partial discharge and high electrical strength of the coil. The inner and outer walls of the winding are reinforced with glass fiber mesh plates, which increases the mechanical strength of the coil and improves the ability of the transformer to withstand sudden short circuits.

2. The low-voltage winding adopts a foil structure, which solves the problem of axial spiral angle when using wire winding, making the ampere turn more balanced. At the same time, the coil adopts axial cooling air duct, enhancing the heat dissipation capacity. The DMD epoxy resin pre impregnated cloth is used between the winding layers, and the overall solidification is formed.

3. The iron core is made of high-quality cold rolled silicon steel sheets, with a three-stage fully inclined joint structure. The core column is bound with F-class weft free straps, and the surface is wrapped with epoxy resin to reduce no-load loss, no-load current, and core noise. The clamps and fasteners are with special surface treatment, further improving the appearance quality of the transformer.

4. The transformer is equipped with a cross flow top blowing cooling fan, it is with low noise, high wind pressure, and beautiful appearance, enhancing the overload capacity of the transformer.

5. The transformer is equipped with an intelligent temperature controller, which improves the operational safety and reliability.

6. The casing can provide the further safety protection for the transformer, with the protection levels of IP20, IP23, IP30, IP33, etc. And the casing materials include aluminum alloy, cold rolled steel plate, stainless steel, etc.

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| SCB10-30 | 30 | 6 6.3 6.6 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 190 | 710 | 2 | 4 |

SCB10-50 | 50 | 270 | 1000 | 2 | 4 | ||||

SCB10-80 | 80 | 370 | 1380 | 1.5 | 4 | ||||

SCB10-100 | 100 | 400 | 1570 | 1.5 | 4 | ||||

SCB10-125 | 125 | 470 | 1850 | 1.3 | 4 | ||||

SCB10-160 | 160 | 540 | 2130 | 1.3 | 4 | ||||

SCB10-200 | 200 | 620 | 2530 | 1.1 | 4 | ||||

SCB10-250 | 250 | 720 | 2760 | 1.1 | 4 | ||||

SCB10-315 | 315 | 880 | 3470 | 1 | 4 | ||||

SCB10-400 | 400 | 980 | 3990 | 1 | 4 | ||||

SCB10-500 | 500 | 1160 | 4880 | 1 | 4 | ||||

| SCB10-630 | 630 | 1300 | 5960 | 0.85 | 6 | ||||

SCB10-800 | 800 | 1520 | 6960 | 0.85 | 6 | ||||

SCB10-1000 | 1000 | 1770 | 8130 | 0.85 | 6 | ||||

SCB10-1250 | 1250 | 2090 | 9690 | 0.85 | 6 | ||||

SCB10-1600 | 1600 | 2450 | 11700 | 0.85 | 6 | ||||

SCB10-2000 | 2000 | 3050 | 14400 | 0.7 | 6 | ||||

| SCB10-2500 | 2500 | 3600 | 17100 | 0.7 | 6 | ||||

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

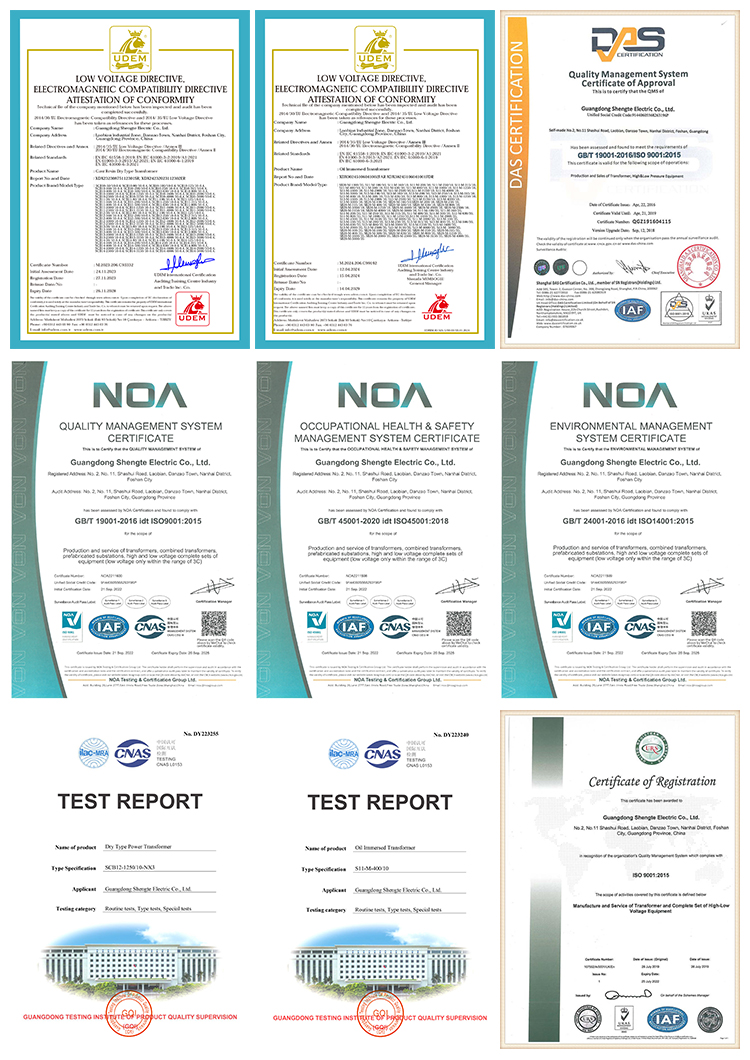

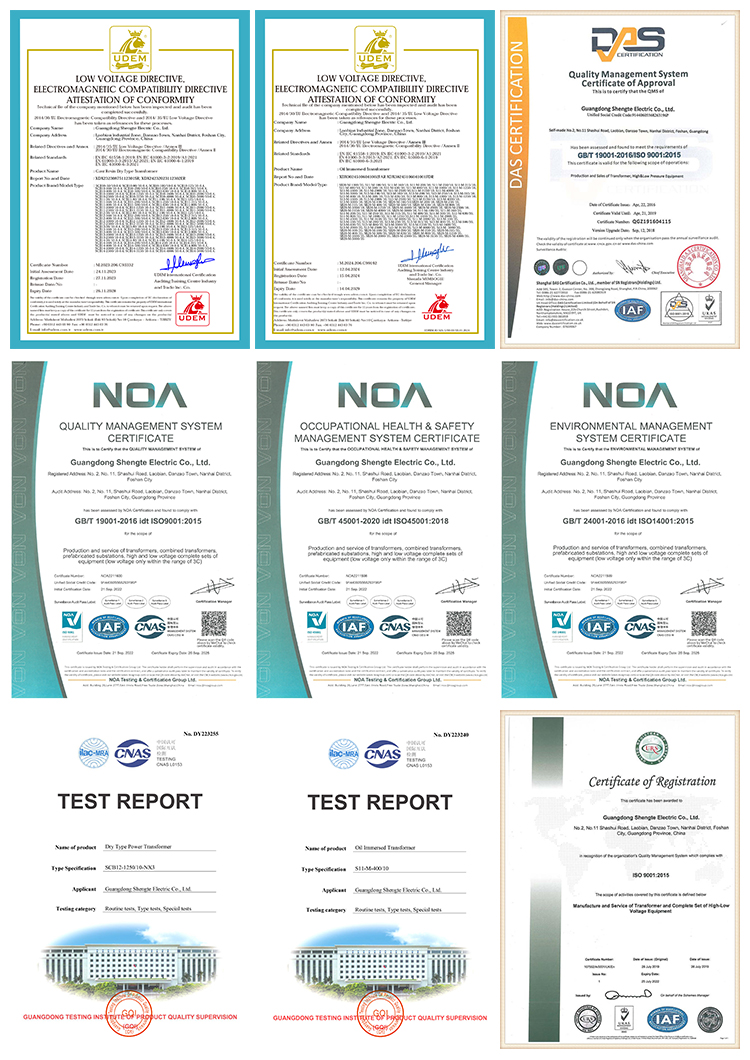

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

Dry type transformer adopts the special insulation materials to isolate current and prevent arcing, its iron core and winding are not immersed in the insulating oil, the cooling methods are divided into natural air cooling and forced air cooling. It is safer in operation, higher reliability and maintenance free.

The dry-type transformer utilizes unique insulation materials to isolate current and prevent arcing. Unlike traditional transformers, its iron core and winding remain unimmersed in insulating oil. Cooling methods are divided into natural air cooling and forced air cooling. This design ensures safer operation, increased reliability, and maintenance-free performance.

Features:

1. Exceptional Efficiency: Low operational losses, minimal noise, and limited partial discharge. The superior heat dissipation allows for operation at 120% of the rated load with forced air cooling.

2. Robust Moisture Resistance: Can operate in up to 100% humidity, with the capability to resume operation post-shutdown without the need for pre-drying.

3. Safety and Environmental Compliance: Fire-resistant and pollution-free, seamlessly integrated within load centers, enhancing operational safety.

4. Advanced Temperature Control: A sophisticated temperature protection system is in place to ensure the transformer's reliability and safe operation.

5. Low Maintenance and Easy Installation: Designed for hassle-free installation and maintenance-free operation, leading to reduced total operational costs.

6. Proven Reliability: Operational studies of units in the field indicate that the transformer's reliability aligns with the highest international standards.

Our Advantages:

1. The high-voltage winding is vacuum cast with epoxy resin filled with fillers, with low partial discharge and high electrical strength of the coil. The inner and outer walls of the winding are reinforced with glass fiber mesh plates, which increases the mechanical strength of the coil and improves the ability of the transformer to withstand sudden short circuits.

2. The low-voltage winding adopts a foil structure, which solves the problem of axial spiral angle when using wire winding, making the ampere turn more balanced. At the same time, the coil adopts axial cooling air duct, enhancing the heat dissipation capacity. The DMD epoxy resin pre impregnated cloth is used between the winding layers, and the overall solidification is formed.

3. The iron core is made of high-quality cold rolled silicon steel sheets, with a three-stage fully inclined joint structure. The core column is bound with F-class weft free straps, and the surface is wrapped with epoxy resin to reduce no-load loss, no-load current, and core noise. The clamps and fasteners are with special surface treatment, further improving the appearance quality of the transformer.

4. The transformer is equipped with a cross flow top blowing cooling fan, it is with low noise, high wind pressure, and beautiful appearance, enhancing the overload capacity of the transformer.

5. The transformer is equipped with an intelligent temperature controller, which improves the operational safety and reliability.

6. The casing can provide the further safety protection for the transformer, with the protection levels of IP20, IP23, IP30, IP33, etc. And the casing materials include aluminum alloy, cold rolled steel plate, stainless steel, etc.

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| SCB10-30 | 30 | 6 6.3 6.6 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 190 | 710 | 2 | 4 |

SCB10-50 | 50 | 270 | 1000 | 2 | 4 | ||||

SCB10-80 | 80 | 370 | 1380 | 1.5 | 4 | ||||

SCB10-100 | 100 | 400 | 1570 | 1.5 | 4 | ||||

SCB10-125 | 125 | 470 | 1850 | 1.3 | 4 | ||||

SCB10-160 | 160 | 540 | 2130 | 1.3 | 4 | ||||

SCB10-200 | 200 | 620 | 2530 | 1.1 | 4 | ||||

SCB10-250 | 250 | 720 | 2760 | 1.1 | 4 | ||||

SCB10-315 | 315 | 880 | 3470 | 1 | 4 | ||||

SCB10-400 | 400 | 980 | 3990 | 1 | 4 | ||||

SCB10-500 | 500 | 1160 | 4880 | 1 | 4 | ||||

| SCB10-630 | 630 | 1300 | 5960 | 0.85 | 6 | ||||

SCB10-800 | 800 | 1520 | 6960 | 0.85 | 6 | ||||

SCB10-1000 | 1000 | 1770 | 8130 | 0.85 | 6 | ||||

SCB10-1250 | 1250 | 2090 | 9690 | 0.85 | 6 | ||||

SCB10-1600 | 1600 | 2450 | 11700 | 0.85 | 6 | ||||

SCB10-2000 | 2000 | 3050 | 14400 | 0.7 | 6 | ||||

| SCB10-2500 | 2500 | 3600 | 17100 | 0.7 | 6 | ||||

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

Analysis and Solution for The Failure of 35kV Dry-Type Transformer Lightning Impulse Test

Why Dry-Type Transformers Are Superior to Oil-Immersed Transformers in Cold Climates

How to Choose The Ideal Transformer Quantity and Capacity for Maximum Efficiency

Analysis of Causes of Failure in High-Voltage Foil-Wound Dry-Type Transformers

Maintenance Requirements for Dry Type and Oil-Immersed Transformers