- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Oil Transformer Iron Core

SHENGTE

| Availability: | |

|---|---|

| Quantity: | |

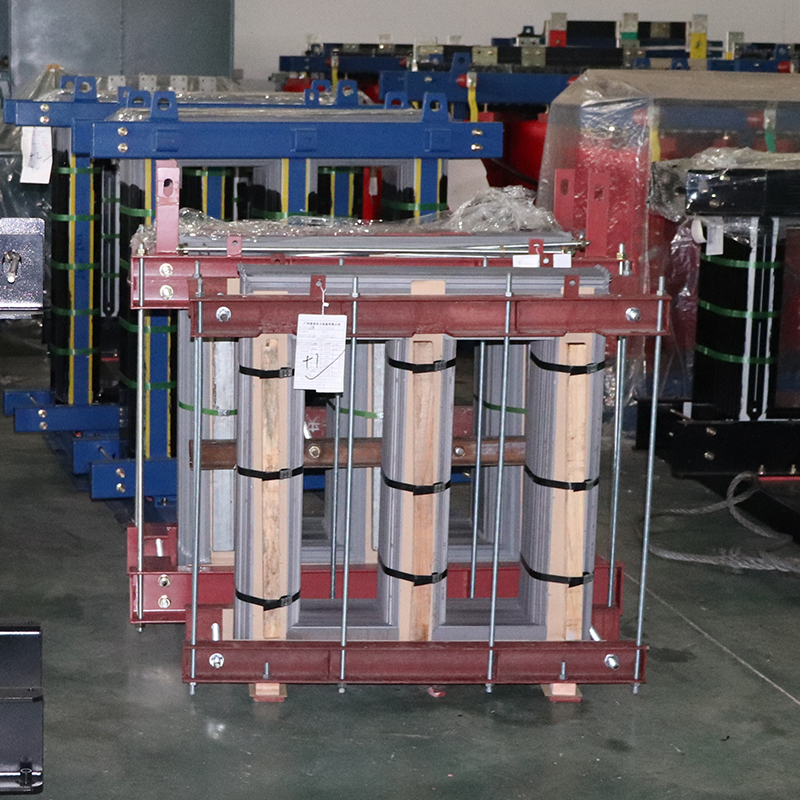

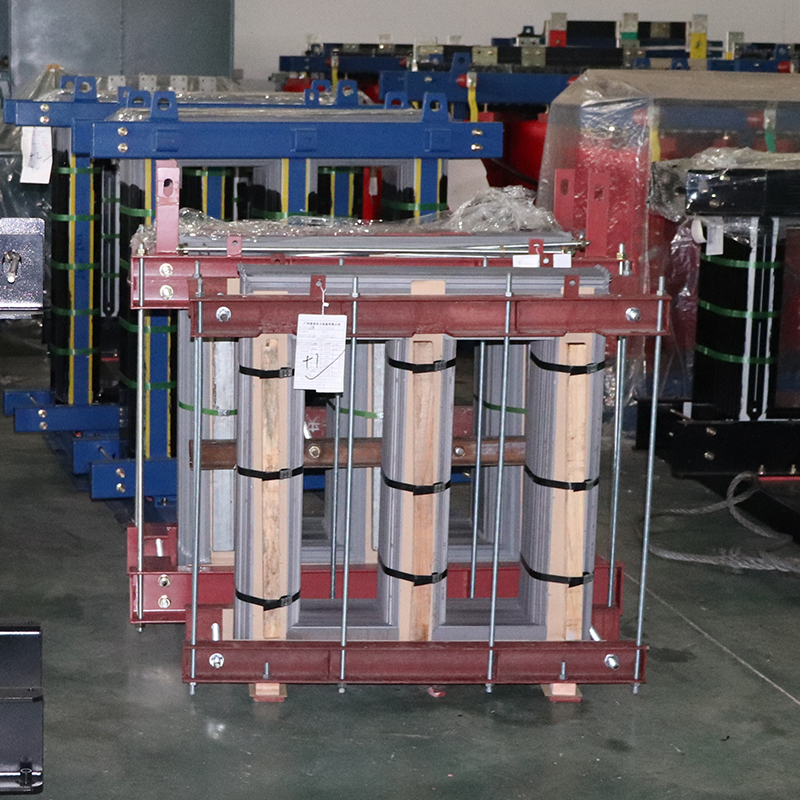

The commonly used transformer iron core is generally made of silicon steel sheets. Silicon steel is a type of silicon alloy steel with a silicon content of 1.0-4.5% and a carbon content of less than 0.08%. It has the characteristics of high magnetic permeability, low coercivity, and high resistance coefficient, so the hysteresis loss and eddy current loss are small, making it an excellent magnetic material for manufacturing iron cores.

SHENGTE uses the high-quality oriented silicon steel for manufacturing the transformer iron core. It's a specialized low-carbon silicon iron alloy with a silicon content of 0.5% to 4.5%. The iron core adopts the stacked structure, it is composed of the silicon steel sheets with thickness less than 0.35mm and high magnetic conductivity, which can reduce the no-load loss and no-load current of the transformer.

As a leading manufacturer in China, we specialize in supplying high-quality transformer winding coils, epoxy-encased conductors, and iron core as spare parts for transformer assembly factories worldwide. Our products include resin-coated copper and aluminum windings, vacuum-cast transformer coils, and precision-crafted transformer iron core components, all engineered to meet international standards. These components ensure excellent compatibility, durability, and performance across a variety of transformer applications.

We pride ourselves on offering cost-effective and reliable solutions, including resin-encapsulated conductors, transformer iron core, and low-loss transformer components, tailored to the needs of transformer assembly operations in diverse industries. Partner with us for precision-crafted transformer coils, transformer iron cores, and dependable service that supports your business success.

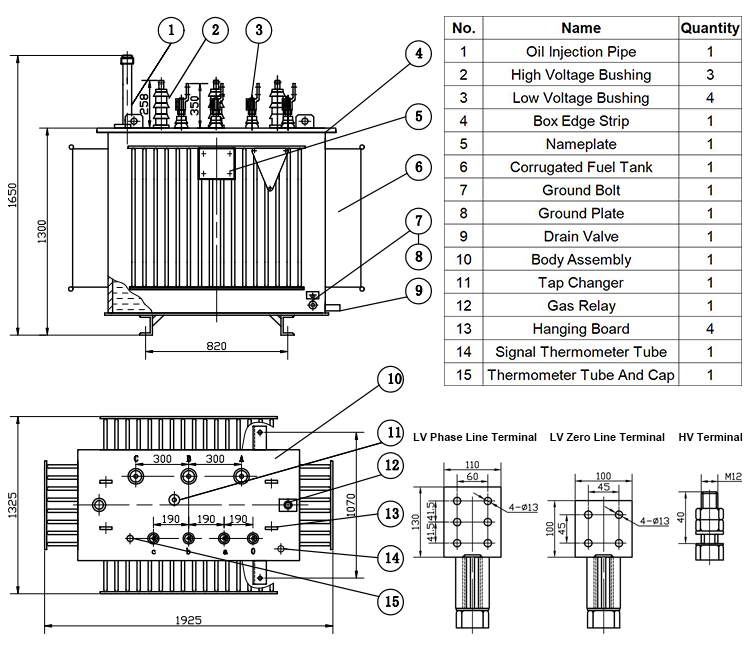

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| S11-M-30 | 30 | 6 6.3 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 100 | 630/600 | 1.5 | 4 |

S11-M-50 | 50 | 130 | 910/870 | 1.3 | 4 | ||||

S11-M-63 | 63 | 150 | 1090/1040 | 1.2 | 4 | ||||

S11-M-80 | 80 | 180 | 1310/1250 | 1.2 | 4 | ||||

S11-M-100 | 100 | 200 | 1580/1500 | 1.1 | 4 | ||||

S11-M-125 | 125 | 240 | 1890/1800 | 1.1 | 4 | ||||

S11-M-160 | 160 | 280 | 2310/2200 | 1 | 4 | ||||

S11-M-200 | 200 | 340 | 2730/2600 | 1 | 4 | ||||

S11-M-250 | 250 | 400 | 3200/3050 | 0.9 | 4 | ||||

S11-M-315 | 315 | 480 | 3830/3650 | 0.9 | 4 | ||||

S11-M-400 | 400 | 570 | 4520/4300 | 0.8 | 4 | ||||

S11-M-500 | 500 | 680 | 5410/5150 | 0.8 | 4 | ||||

S11-M-630 | 630 | 810 | 6200 | 0.6 | 4.5 | ||||

S11-M-800 | 800 | 980 | 7500 | 0.6 | 4.5 | ||||

S11-M-1000 | 1000 | 1150 | 10300 | 0.6 | 4.5 | ||||

S11-M-1250 | 1250 | 1360 | 12000 | 0.5 | 4.5 | ||||

S11-M-1600 | 1600 | 1640 | 14500 | 0.5 | 4.5 | ||||

S11-M-2000 | 2000 | 1940 | 18300 | 0.4 | 5 | ||||

S11-M-2500 | 2500 | 2290 | 21200 | 0.4 | 5 | ||||

S11-M-3150 | 3150 | 2730 | 24300 | 0.4 | 5 | ||||

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

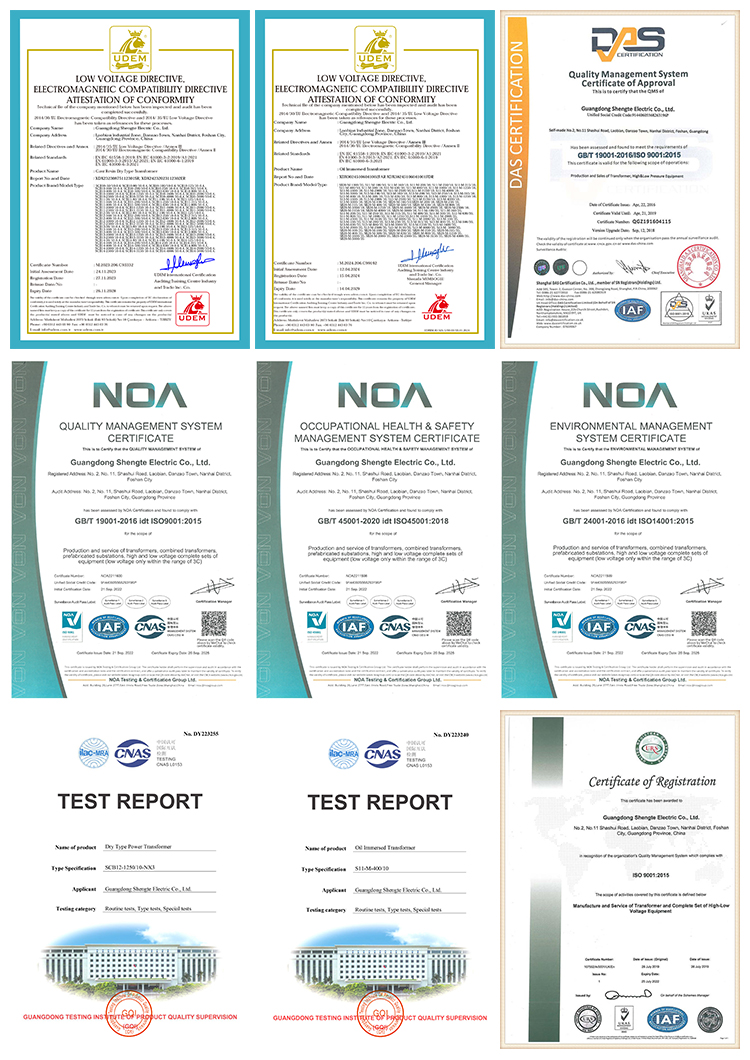

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

The commonly used transformer iron core is generally made of silicon steel sheets. Silicon steel is a type of silicon alloy steel with a silicon content of 1.0-4.5% and a carbon content of less than 0.08%. It has the characteristics of high magnetic permeability, low coercivity, and high resistance coefficient, so the hysteresis loss and eddy current loss are small, making it an excellent magnetic material for manufacturing iron cores.

SHENGTE uses the high-quality oriented silicon steel for manufacturing the transformer iron core. It's a specialized low-carbon silicon iron alloy with a silicon content of 0.5% to 4.5%. The iron core adopts the stacked structure, it is composed of the silicon steel sheets with thickness less than 0.35mm and high magnetic conductivity, which can reduce the no-load loss and no-load current of the transformer.

As a leading manufacturer in China, we specialize in supplying high-quality transformer winding coils, epoxy-encased conductors, and iron core as spare parts for transformer assembly factories worldwide. Our products include resin-coated copper and aluminum windings, vacuum-cast transformer coils, and precision-crafted transformer iron core components, all engineered to meet international standards. These components ensure excellent compatibility, durability, and performance across a variety of transformer applications.

We pride ourselves on offering cost-effective and reliable solutions, including resin-encapsulated conductors, transformer iron core, and low-loss transformer components, tailored to the needs of transformer assembly operations in diverse industries. Partner with us for precision-crafted transformer coils, transformer iron cores, and dependable service that supports your business success.

| Model | Rated Capacity (KVA) | Rated Voltage (KV) | Connection Method | No-load Loss (W) | Load Loss (W) | No-load Current (%) | Short Circuit Impedance (%) | ||

| High Voltage | Voltage Regulation Range | Low Voltage | |||||||

| S11-M-30 | 30 | 6 6.3 10 10.5 11 | ±5% ±2×2.5% | 0.4 | Yyn0 Dyn11 | 100 | 630/600 | 1.5 | 4 |

S11-M-50 | 50 | 130 | 910/870 | 1.3 | 4 | ||||

S11-M-63 | 63 | 150 | 1090/1040 | 1.2 | 4 | ||||

S11-M-80 | 80 | 180 | 1310/1250 | 1.2 | 4 | ||||

S11-M-100 | 100 | 200 | 1580/1500 | 1.1 | 4 | ||||

S11-M-125 | 125 | 240 | 1890/1800 | 1.1 | 4 | ||||

S11-M-160 | 160 | 280 | 2310/2200 | 1 | 4 | ||||

S11-M-200 | 200 | 340 | 2730/2600 | 1 | 4 | ||||

S11-M-250 | 250 | 400 | 3200/3050 | 0.9 | 4 | ||||

S11-M-315 | 315 | 480 | 3830/3650 | 0.9 | 4 | ||||

S11-M-400 | 400 | 570 | 4520/4300 | 0.8 | 4 | ||||

S11-M-500 | 500 | 680 | 5410/5150 | 0.8 | 4 | ||||

S11-M-630 | 630 | 810 | 6200 | 0.6 | 4.5 | ||||

S11-M-800 | 800 | 980 | 7500 | 0.6 | 4.5 | ||||

S11-M-1000 | 1000 | 1150 | 10300 | 0.6 | 4.5 | ||||

S11-M-1250 | 1250 | 1360 | 12000 | 0.5 | 4.5 | ||||

S11-M-1600 | 1600 | 1640 | 14500 | 0.5 | 4.5 | ||||

S11-M-2000 | 2000 | 1940 | 18300 | 0.4 | 5 | ||||

S11-M-2500 | 2500 | 2290 | 21200 | 0.4 | 5 | ||||

S11-M-3150 | 3150 | 2730 | 24300 | 0.4 | 5 | ||||

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.