- All

- Product Name

- Product Keyword

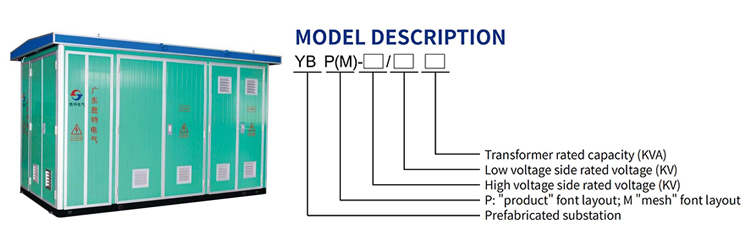

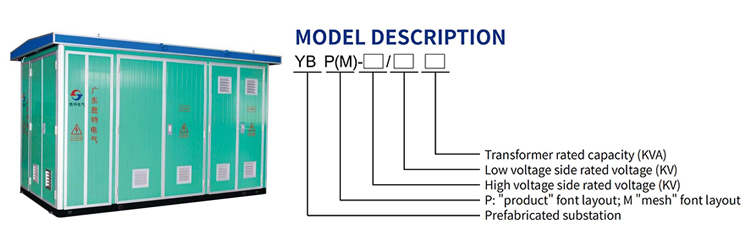

- Product Model

- Product Summary

- Product Description

- Multi Field Search

YBP-10/0.4-315

SHENGTE

| Availability: | |

|---|---|

| Quantity: | |

The European box-type prefabricated substation complies with GB/T17467-1998 and IEC1330 standards, featuring easy installation, low loss, minimal noise, and strong resistance to short circuits and overloads. It is suitable for various settings such as commercial centers, residential areas, industrial sites, hospitals, schools, airports, stations, ports, subways, and more.

Features:

1. Offers "Cross-shaped" and "T-shaped" layout options for different preferences.

2. Built using high-quality materials, including aluminum alloy, stainless steel, composite, and glass fiber reinforced cement, for long-lasting durability.

3. The base, made from galvanized channel steel or cement, ensures excellent corrosion resistance and mechanical strength.

4. A double-layer top cover provides excellent heat insulation, radiation protection, and ventilation.

5. Each room within the substation is partitioned with iron plates and equipped with lighting and transformer tops for ease of use.

6. The transformer room features an automatic exhaust device for optimal temperature control.

7. Customizable color options ensure the substation blends seamlessly with its environment and enhances aesthetic appeal.

Our Advantages:

1. The prefabricated substation utilizes advanced international technology, adapted for local conditions. Made from 304 stainless steel, it offers robust construction, excellent thermal insulation, effective ventilation, and resistance to dust, moisture, and corrosion. The structure is rust-free, attractive, and easy to maintain.

2. The high-voltage side includes load switches or vacuum circuit breakers for full protection against misoperation, overloads, and short circuits, employing XGN15-12 or HXGN2-12 ring network switchgear. The low-voltage side uses MNS, GCK, or GCS switchgear, with options for either oil-immersed or dry-type transformers.

3. This substation provides comprehensive protection and ease of operation. High and low voltage metering options are available, and automatic reactive power compensation devices can be installed as required, with options for dynamic or static hybrid compensation.

4. The double-layer top cover, insulated with foam plastics, provides excellent heat insulation, radiation protection, and ventilation. The high and low voltage compartments have separate top plates, while the transformer room includes anti-condensation, automatic temperature control, heating, and cooling devices.

5. Natural ventilation is standard, with the option for forced ventilation equipment. Dust prevention devices are installed at louver positions on the door and side panels.

6. Intelligent lighting energy-saving devices are incorporated, significantly reducing lighting electricity consumption and lowering operational costs.

Item | Unit | High Voltage Side | Transformer | Low Voltage Side |

Rated Frequency | Hz | -- | 50 | -- |

Rated Capacity | KVA | -- | 100 ~ 1600 | -- |

Rated Voltage | KV | 6 / 10 / 11 / 12 | 6 / 10 / 11 / 12, 0.4 | 0.4 |

Rated Current | A | 200 ~ 630 | -- | 100 ~ 3000 |

| Rated Breaking Current | A | 400 ~ 630 | -- | 15 ~ 63 |

Rated Short-Time Withstand Current | KA/S | 20 / 2 | -- | 15 / 1 |

| Rated Peak Withstand Current | KA | 31.5 / 50 | -- | 30 |

| Rated Making Current | KA | 31.5 / 50 | -- | -- |

1 Minute Power Frequency Withstand Current | KV | Phase to Ground, Phase to Phase: 30 / 42 | Oil Type: 35 / 5min | 2 |

| Isolation Clearance: 34 / 48 | Dry Type: 28 / 5min | 2.5 | ||

Lightning Impulse Withstand Voltage | KV | Phase to Ground, Phase to Phase: 60 / 75 | 75 | -- |

| Isolation Clearance: 75 / 85 | 75 | -- | ||

Tapping Range | -- | -- | ±2 × 2.5% | -- |

| Impedance Voltage | -- | -- | 4% / 4.5% | -- |

| Connection Group | -- | -- | Yyn0 / Dyn11 | -- |

Protection Class | -- | -- | IP23 | -- |

Noise Level | dB | -- | Oil Type: <55 | -- |

-- | Dry Type: <65 | -- |

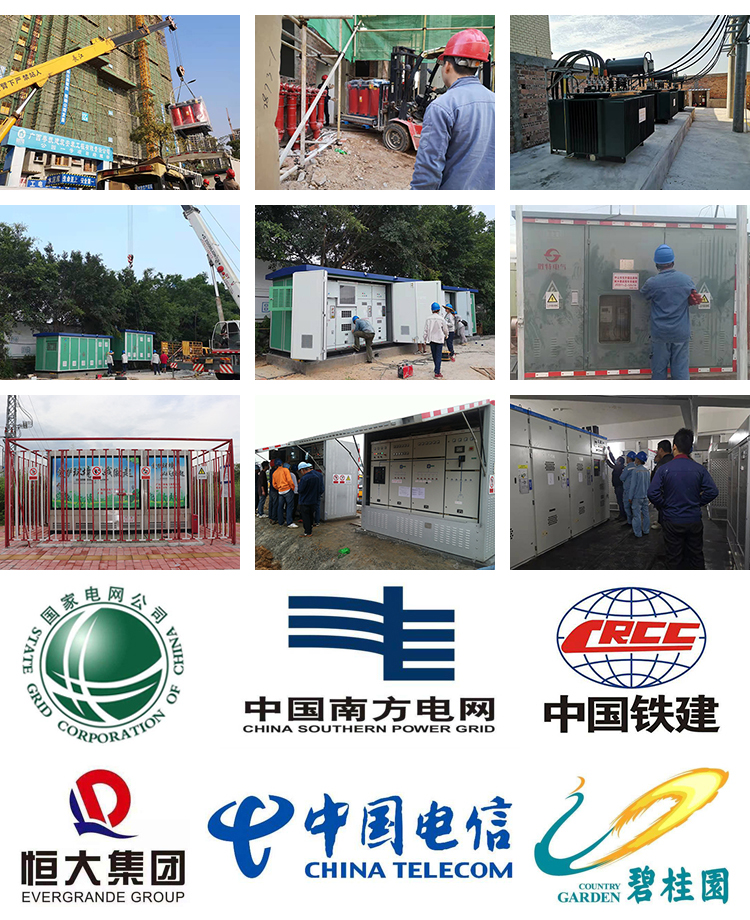

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

The European box-type prefabricated substation complies with GB/T17467-1998 and IEC1330 standards, featuring easy installation, low loss, minimal noise, and strong resistance to short circuits and overloads. It is suitable for various settings such as commercial centers, residential areas, industrial sites, hospitals, schools, airports, stations, ports, subways, and more.

Features:

1. Offers "Cross-shaped" and "T-shaped" layout options for different preferences.

2. Built using high-quality materials, including aluminum alloy, stainless steel, composite, and glass fiber reinforced cement, for long-lasting durability.

3. The base, made from galvanized channel steel or cement, ensures excellent corrosion resistance and mechanical strength.

4. A double-layer top cover provides excellent heat insulation, radiation protection, and ventilation.

5. Each room within the substation is partitioned with iron plates and equipped with lighting and transformer tops for ease of use.

6. The transformer room features an automatic exhaust device for optimal temperature control.

7. Customizable color options ensure the substation blends seamlessly with its environment and enhances aesthetic appeal.

Our Advantages:

1. The prefabricated substation utilizes advanced international technology, adapted for local conditions. Made from 304 stainless steel, it offers robust construction, excellent thermal insulation, effective ventilation, and resistance to dust, moisture, and corrosion. The structure is rust-free, attractive, and easy to maintain.

2. The high-voltage side includes load switches or vacuum circuit breakers for full protection against misoperation, overloads, and short circuits, employing XGN15-12 or HXGN2-12 ring network switchgear. The low-voltage side uses MNS, GCK, or GCS switchgear, with options for either oil-immersed or dry-type transformers.

3. This substation provides comprehensive protection and ease of operation. High and low voltage metering options are available, and automatic reactive power compensation devices can be installed as required, with options for dynamic or static hybrid compensation.

4. The double-layer top cover, insulated with foam plastics, provides excellent heat insulation, radiation protection, and ventilation. The high and low voltage compartments have separate top plates, while the transformer room includes anti-condensation, automatic temperature control, heating, and cooling devices.

5. Natural ventilation is standard, with the option for forced ventilation equipment. Dust prevention devices are installed at louver positions on the door and side panels.

6. Intelligent lighting energy-saving devices are incorporated, significantly reducing lighting electricity consumption and lowering operational costs.

Item | Unit | High Voltage Side | Transformer | Low Voltage Side |

Rated Frequency | Hz | -- | 50 | -- |

Rated Capacity | KVA | -- | 100 ~ 1600 | -- |

Rated Voltage | KV | 6 / 10 / 11 / 12 | 6 / 10 / 11 / 12, 0.4 | 0.4 |

Rated Current | A | 200 ~ 630 | -- | 100 ~ 3000 |

| Rated Breaking Current | A | 400 ~ 630 | -- | 15 ~ 63 |

Rated Short-Time Withstand Current | KA/S | 20 / 2 | -- | 15 / 1 |

| Rated Peak Withstand Current | KA | 31.5 / 50 | -- | 30 |

| Rated Making Current | KA | 31.5 / 50 | -- | -- |

1 Minute Power Frequency Withstand Current | KV | Phase to Ground, Phase to Phase: 30 / 42 | Oil Type: 35 / 5min | 2 |

| Isolation Clearance: 34 / 48 | Dry Type: 28 / 5min | 2.5 | ||

Lightning Impulse Withstand Voltage | KV | Phase to Ground, Phase to Phase: 60 / 75 | 75 | -- |

| Isolation Clearance: 75 / 85 | 75 | -- | ||

Tapping Range | -- | -- | ±2 × 2.5% | -- |

| Impedance Voltage | -- | -- | 4% / 4.5% | -- |

| Connection Group | -- | -- | Yyn0 / Dyn11 | -- |

Protection Class | -- | -- | IP23 | -- |

Noise Level | dB | -- | Oil Type: <55 | -- |

-- | Dry Type: <65 | -- |

Guangdong Shengte Electric Co., Ltd., based in Foshan, China, is a distinguished transformer manufacturer known for reliability and exceptional after-sales service. With over a decade of experience, we've provided high-quality, cost-efficient transformers for governmental and private sector projects worldwide, earning a reputation for excellence.

Our commitment to quality is demonstrated by meeting the rigorous standards of our German Power Utility clients, ensuring only the highest quality solutions.

Spanning 10,000 square meters, our Foshan facility is equipped with cutting-edge production and testing equipment, enabling us to offer customized solutions, including OEM and ODM services. Our product range includes oil-immersed transformers, resin cast dry-type transformers, pad mounted transformers, prefabricated substations, and more.

Certified by ILAC-MRA and CNAS, our IEC certificate underscores our dedication to international quality standards. Additionally, we hold ISO9001, CE, and Innovative Product Certifications, with active pursuit of the UL certificate to further demonstrate our commitment to global compliance.

Q1: Are you a manufacturer or trading company?

A1: Our factory covers an area of over 10000m2, we can produce 2000 more transformers each year.

Q2: Do you have the relevant certifications and test reports?

A2: Yes, we have ISO9001 and CE certification, and can provide the test reports according to IEC standard.

Q3: How long is the warranty period?

A3: It is 12 months.

Q4: Would you accept using customer's logo?

A4: Yes, we can provide OEM and ODM service.

Q5: What's the MOQ?

A5: It is 1 set.

Q6: What are the payment methods and terms?

A6: We accept T/T, Western Union, PayPal, etc. 30% advance payment before production, 70% balance payment before delivery.

Q7: How long is the delivery time?

A7: Generally it is 20-30 days, it depends on the order quantity.

Q8: What is the standard of package?

A8: Wooden case or special package according to customer's requirement.

content is empty!